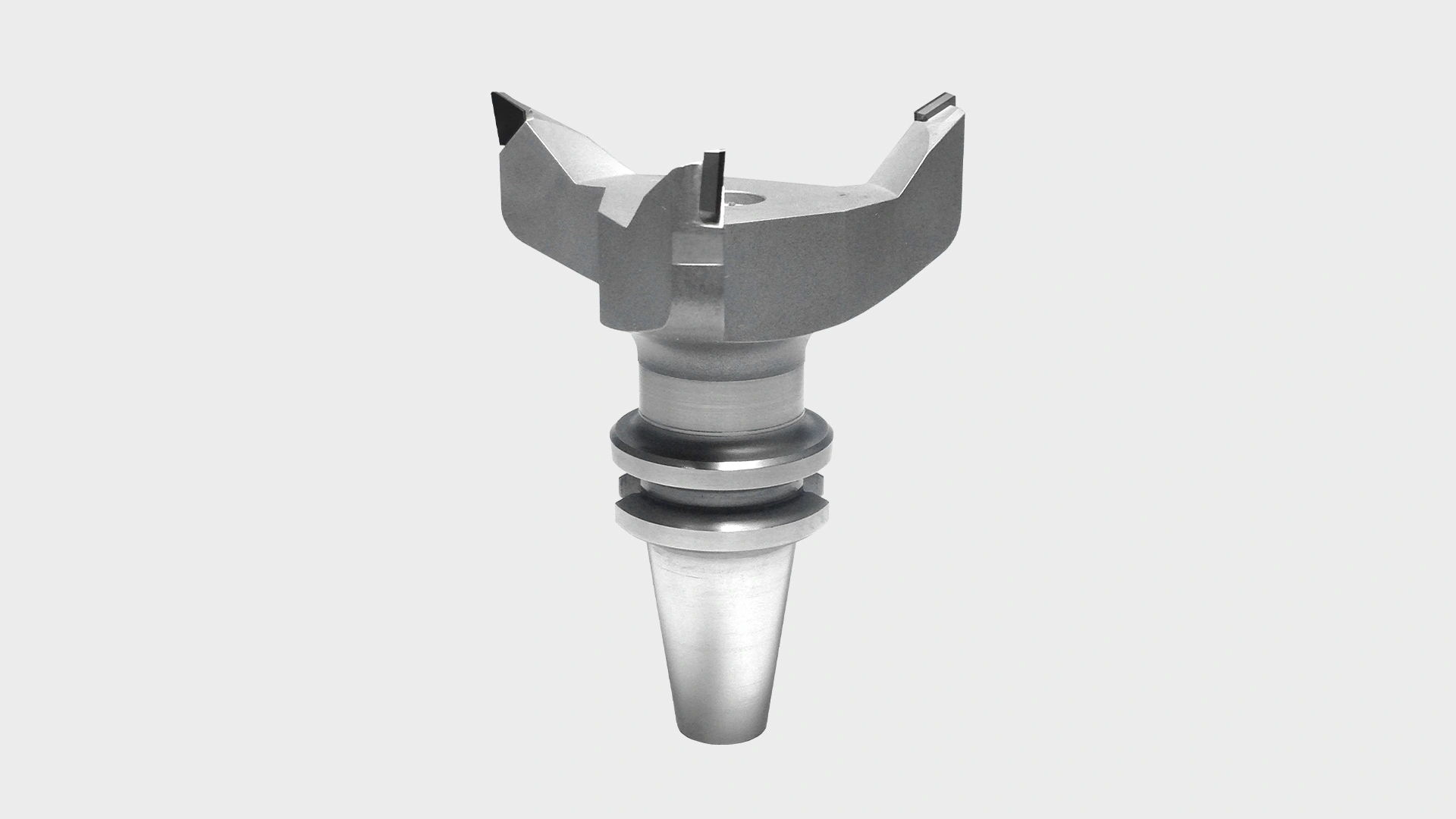

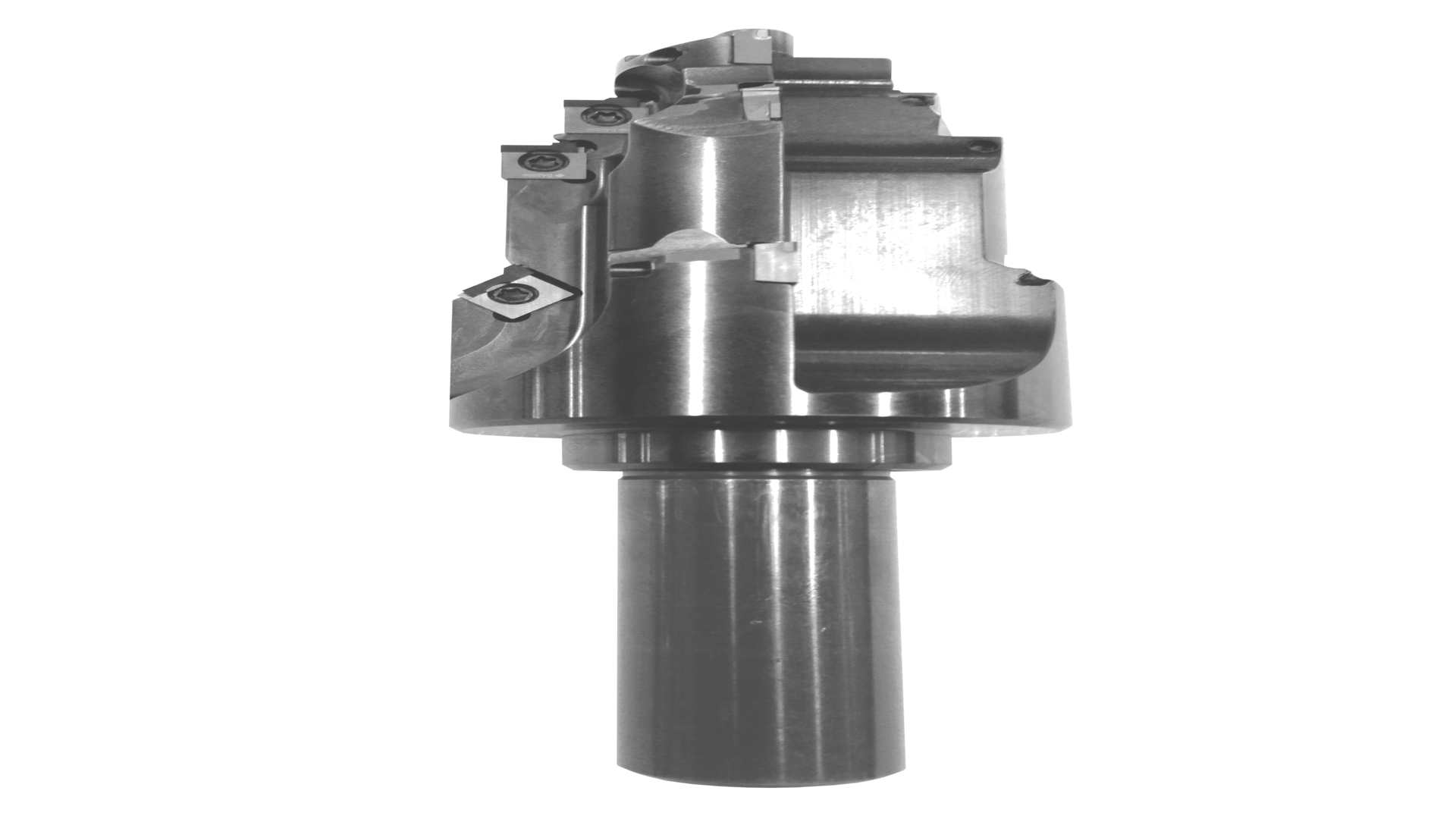

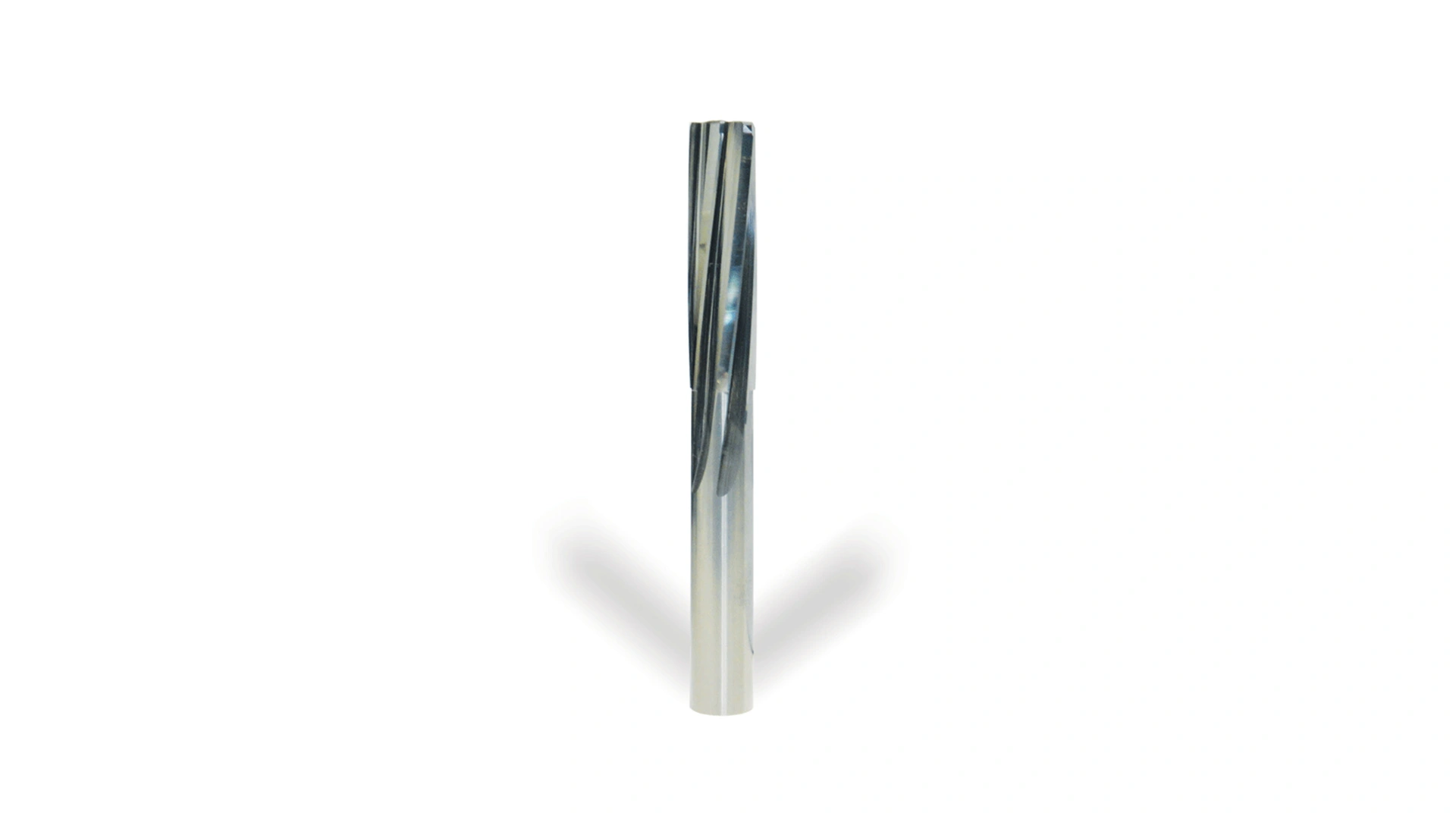

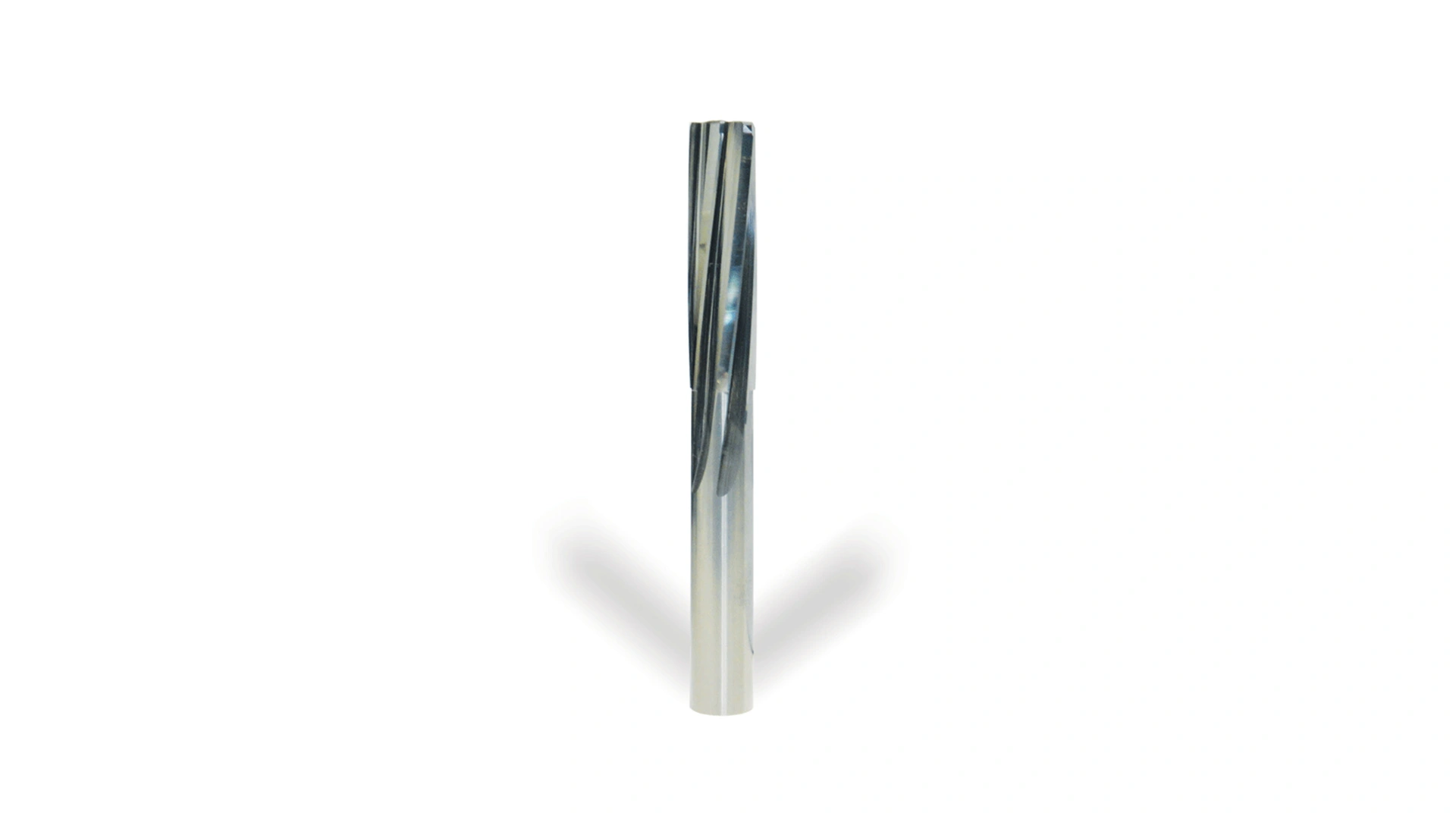

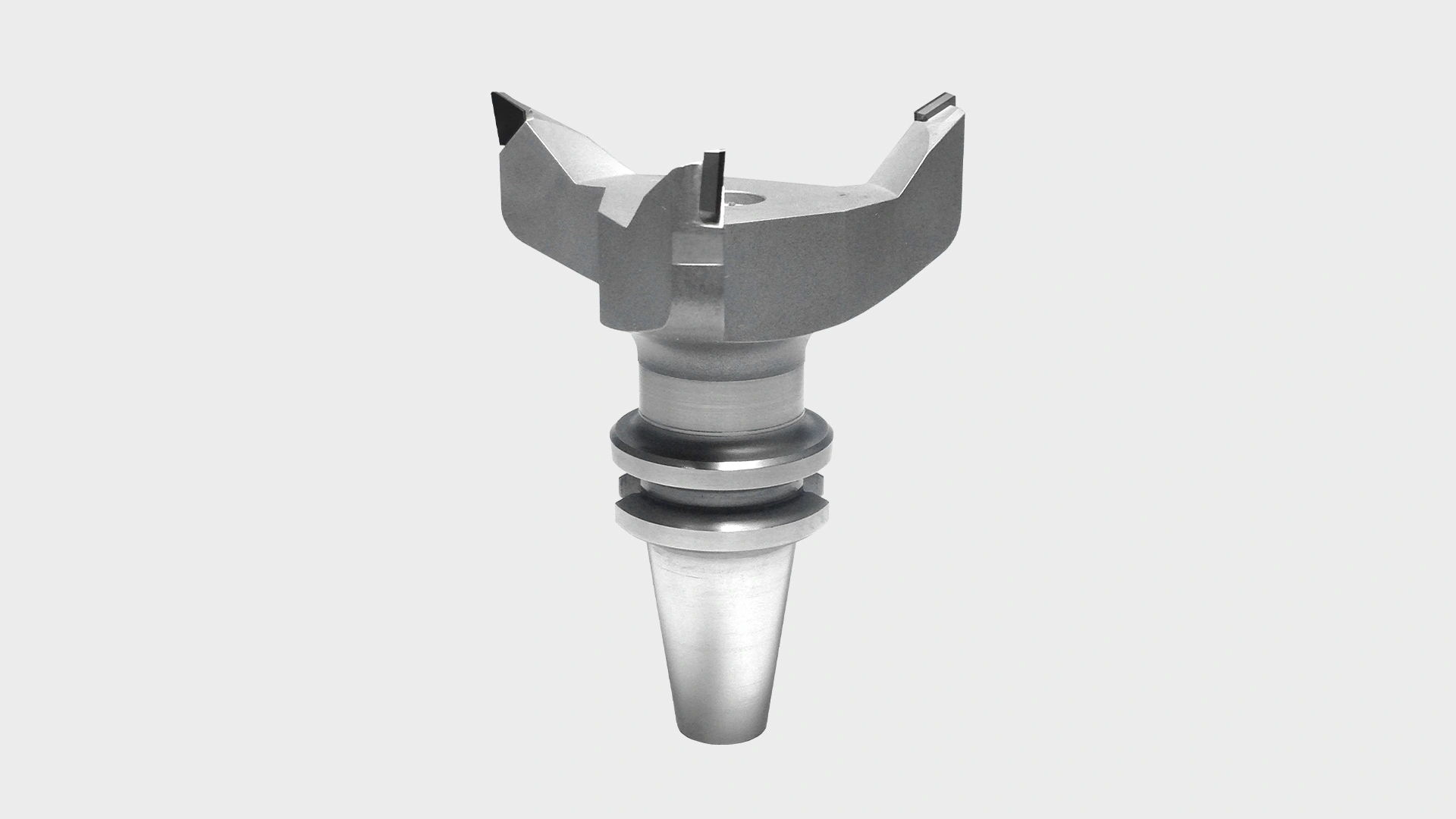

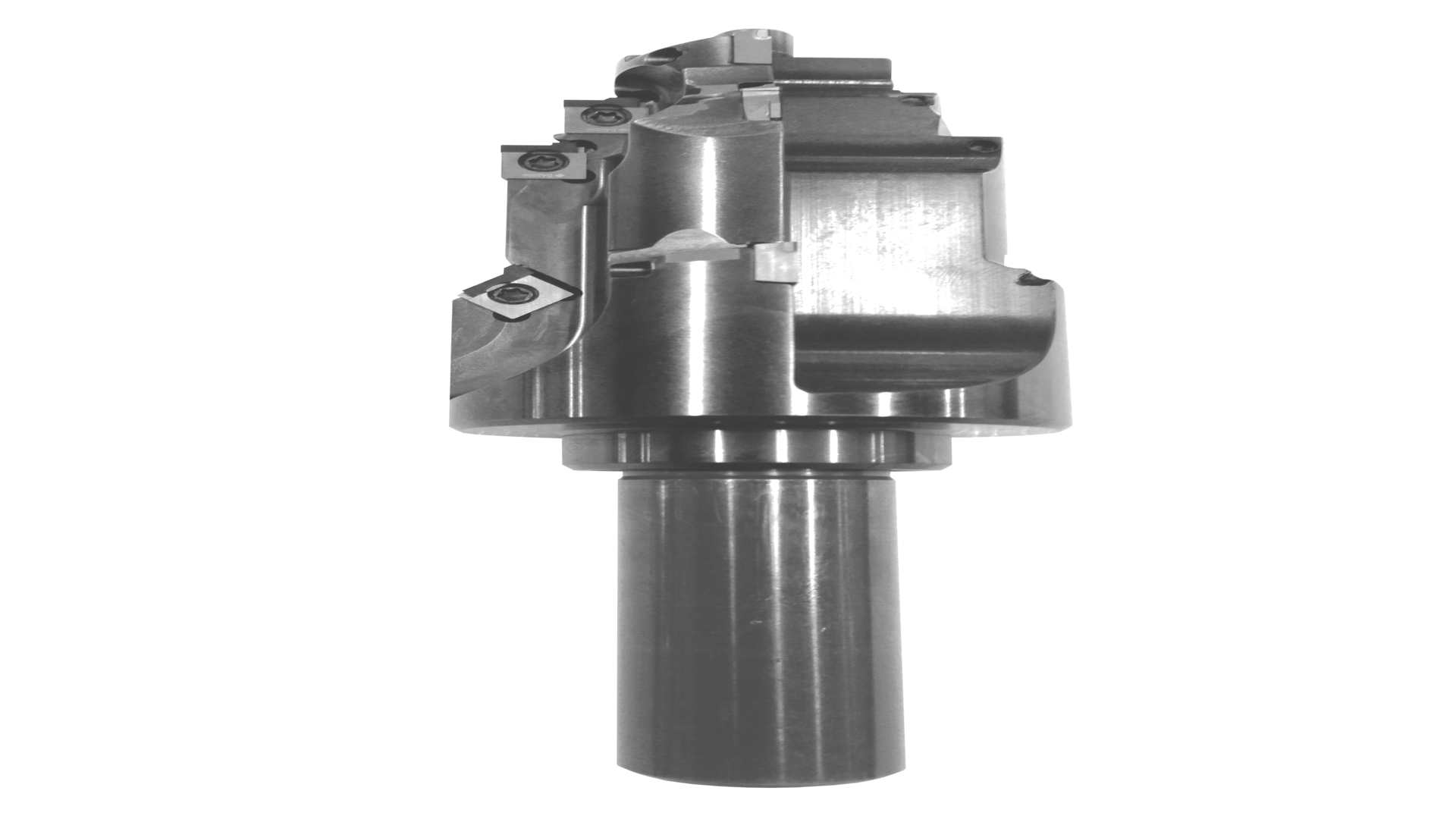

Monocrystalline Diamond or MCD (sometimes called “Mono”) is the most common type of Single Crystal Diamond (SCD), and it is generally the most economical. High pressure high temperature (HPHT) process is used to synthesize MCD where diamond crystals slowly form from a carbon-based mixture under extremely high pressure and temperature. The process mimics the natural process in a controlled environment. The diamond created from this process has a yellow tint. MCD cutting tool is most suitable for finishing operations that require “polished” or mirror-like surface finish. Same as every diamond cutting tool, it is suitable for non-ferreous materials such as, aluminum, copper, brass, precious metals, plastics, etc… Industries that commonly use MCD cutting tools in their manufacturing process include, automotive, optical lens, jewely, watch, etc.