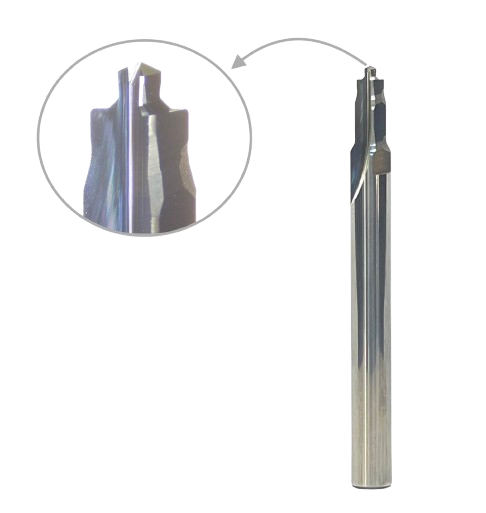

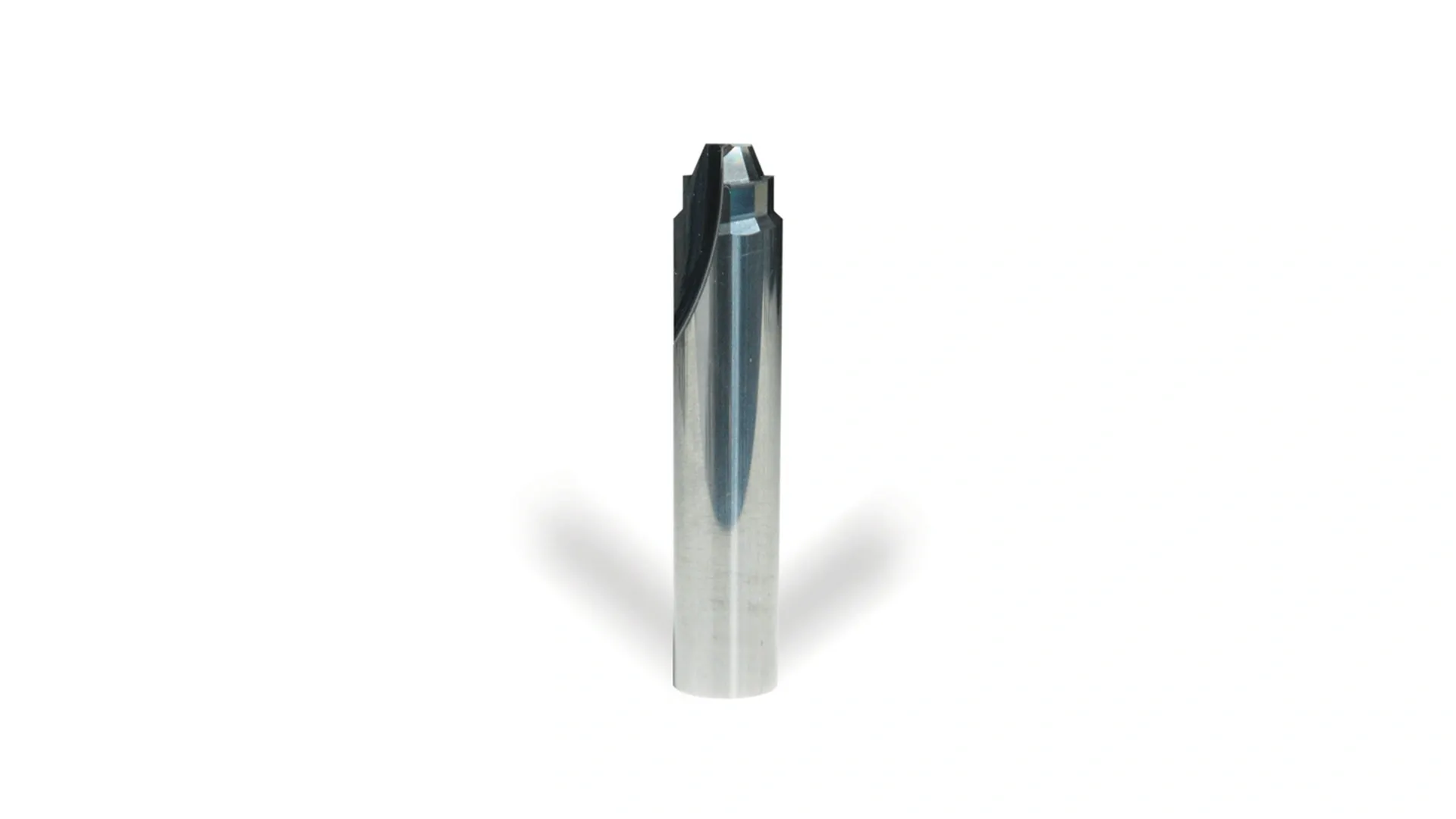

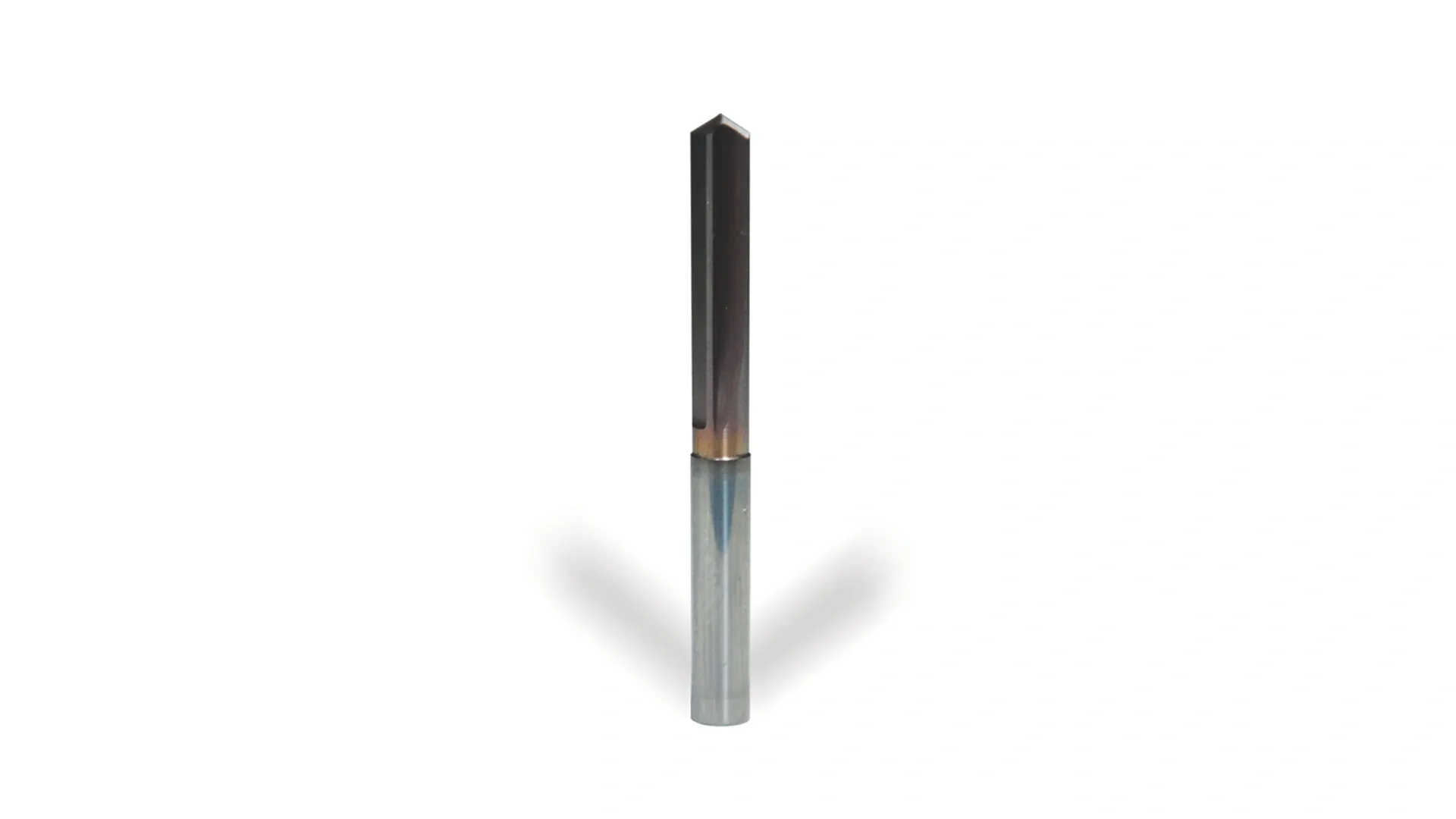

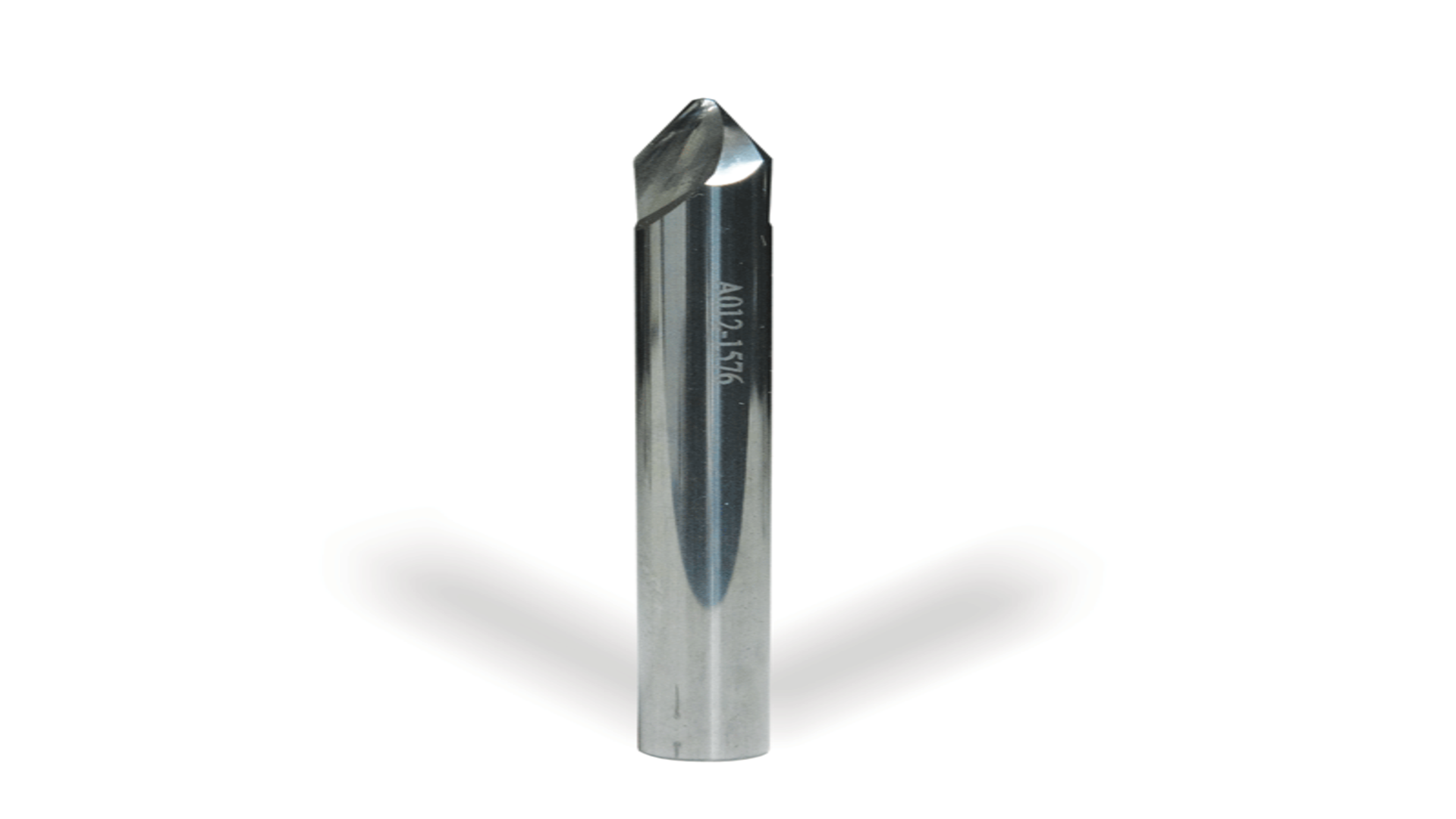

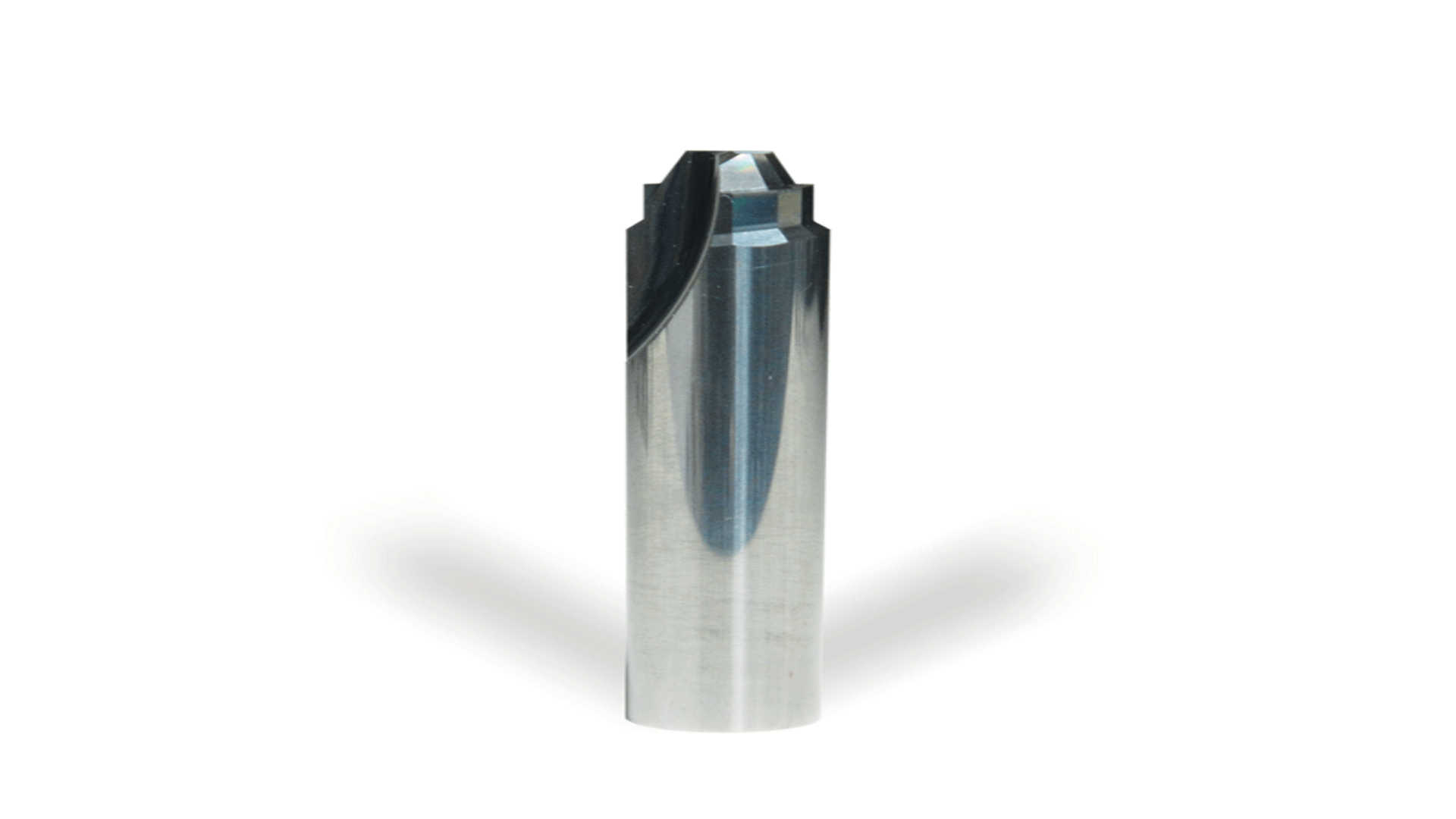

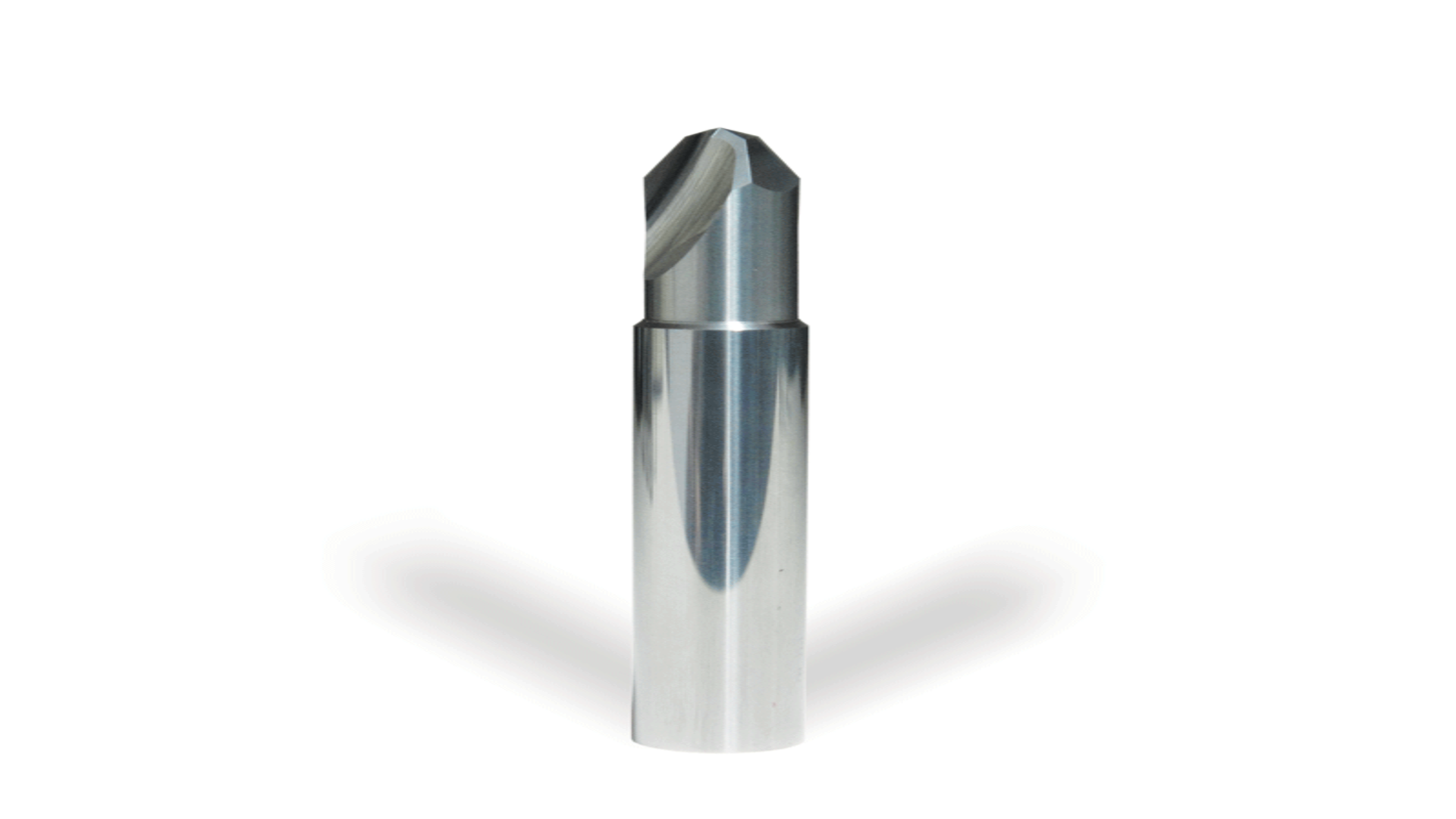

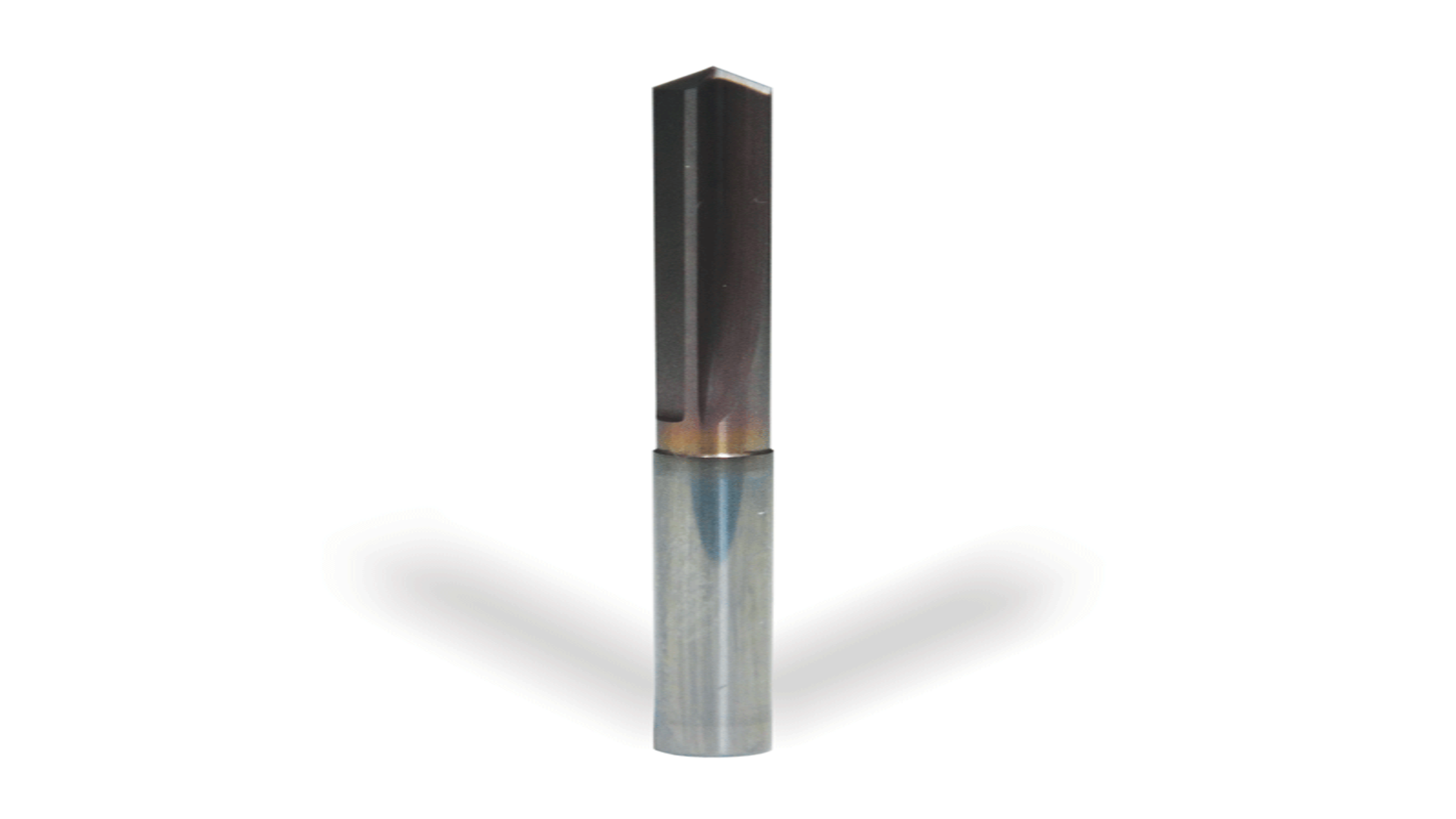

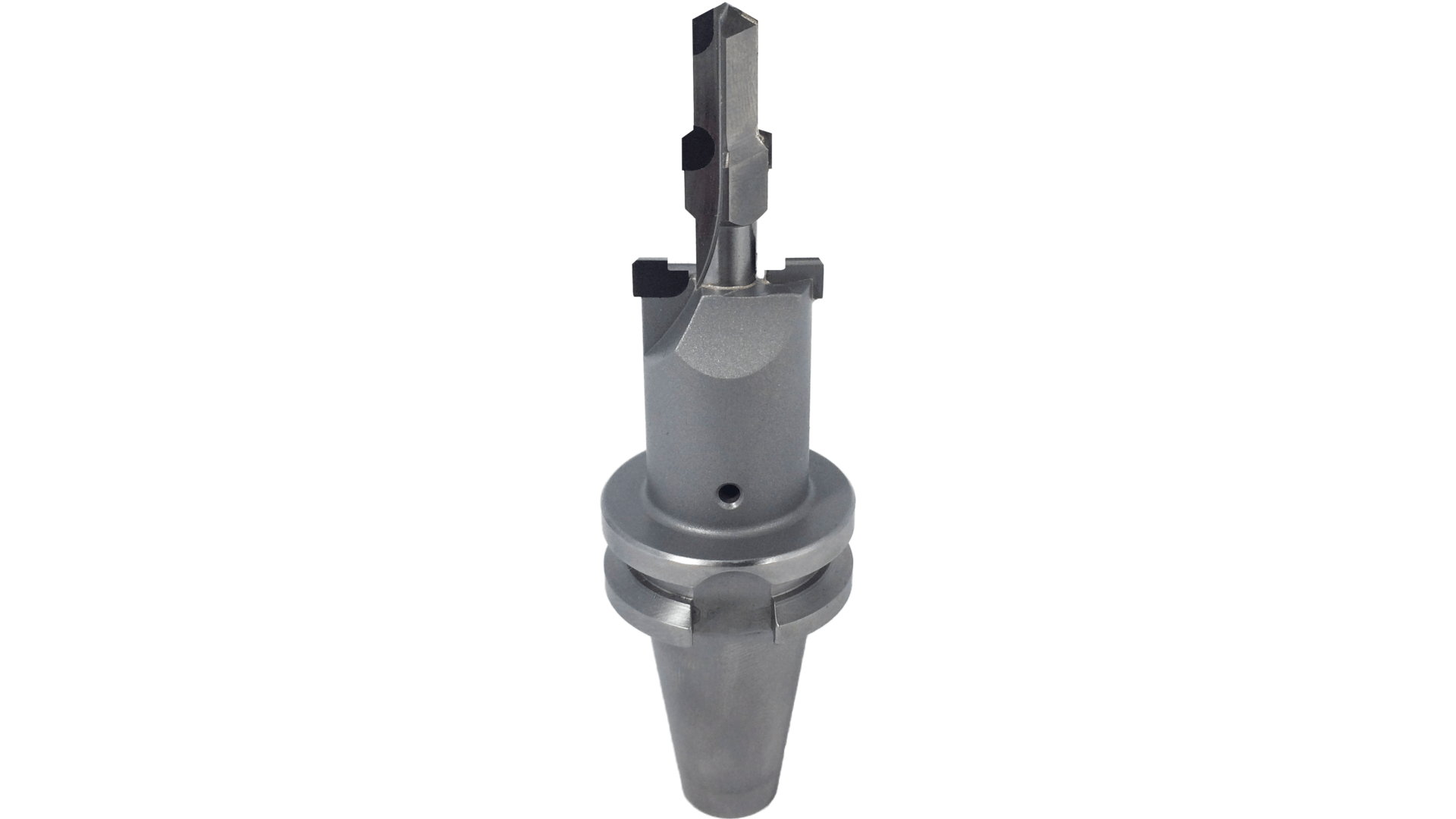

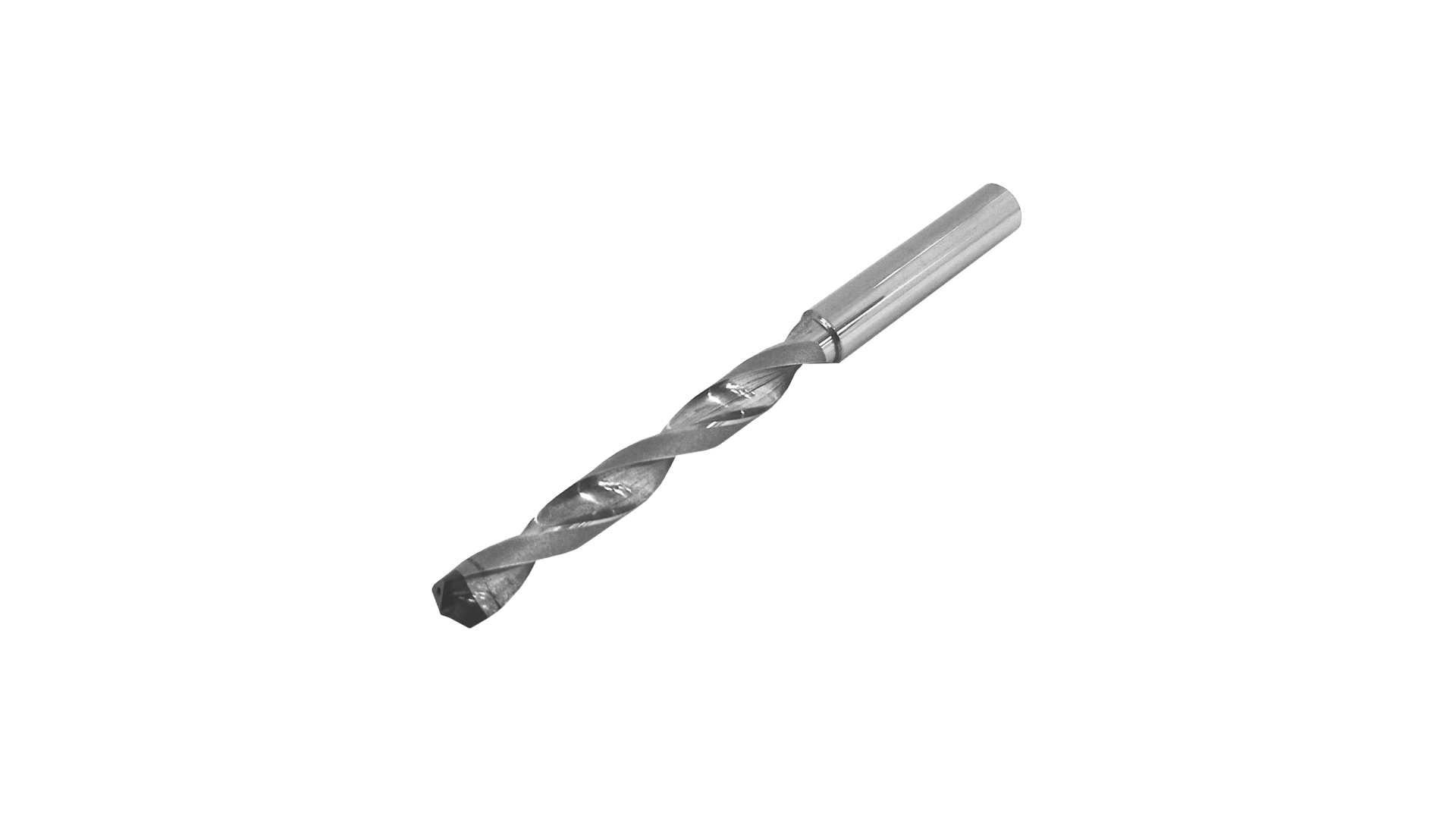

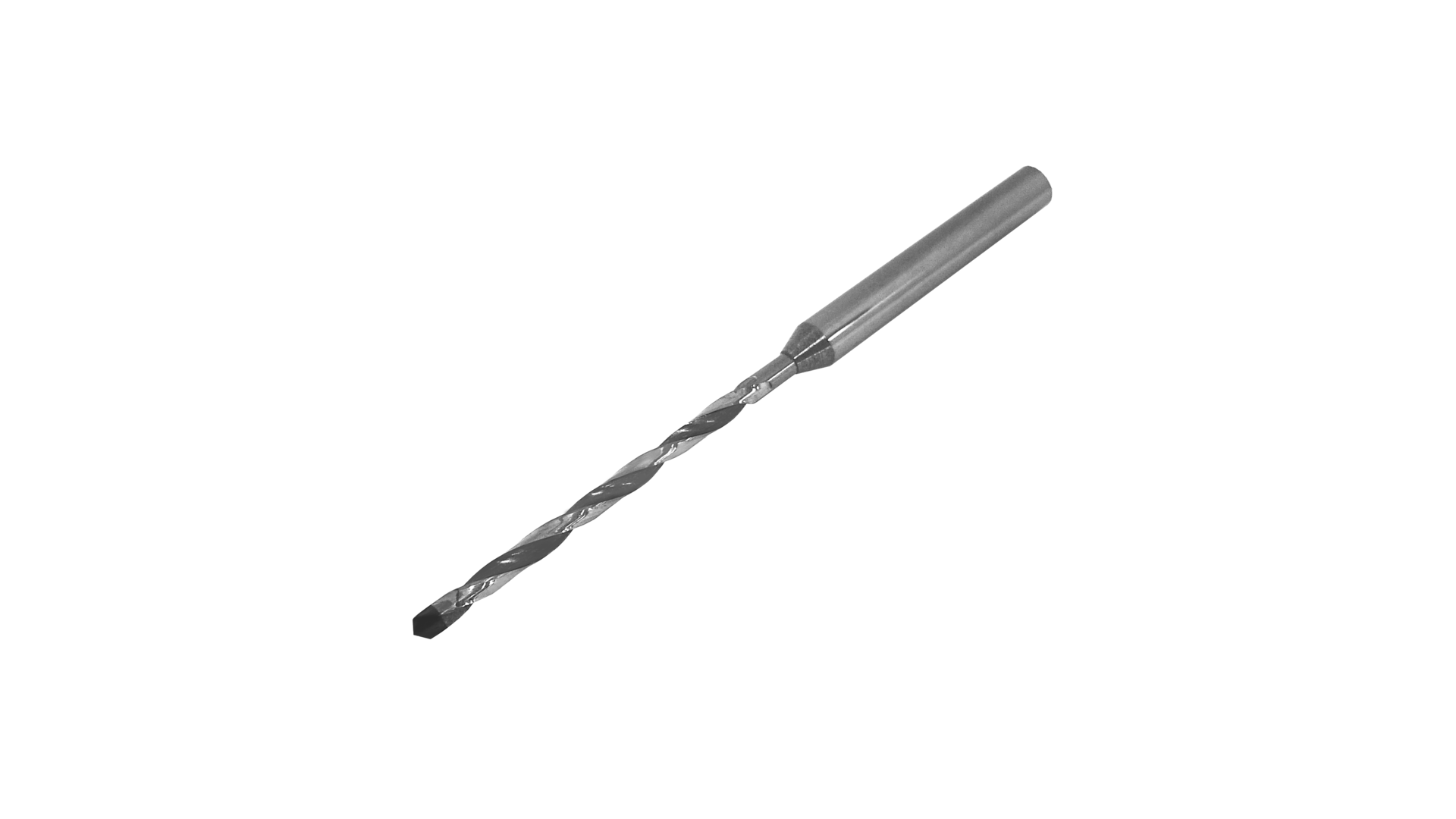

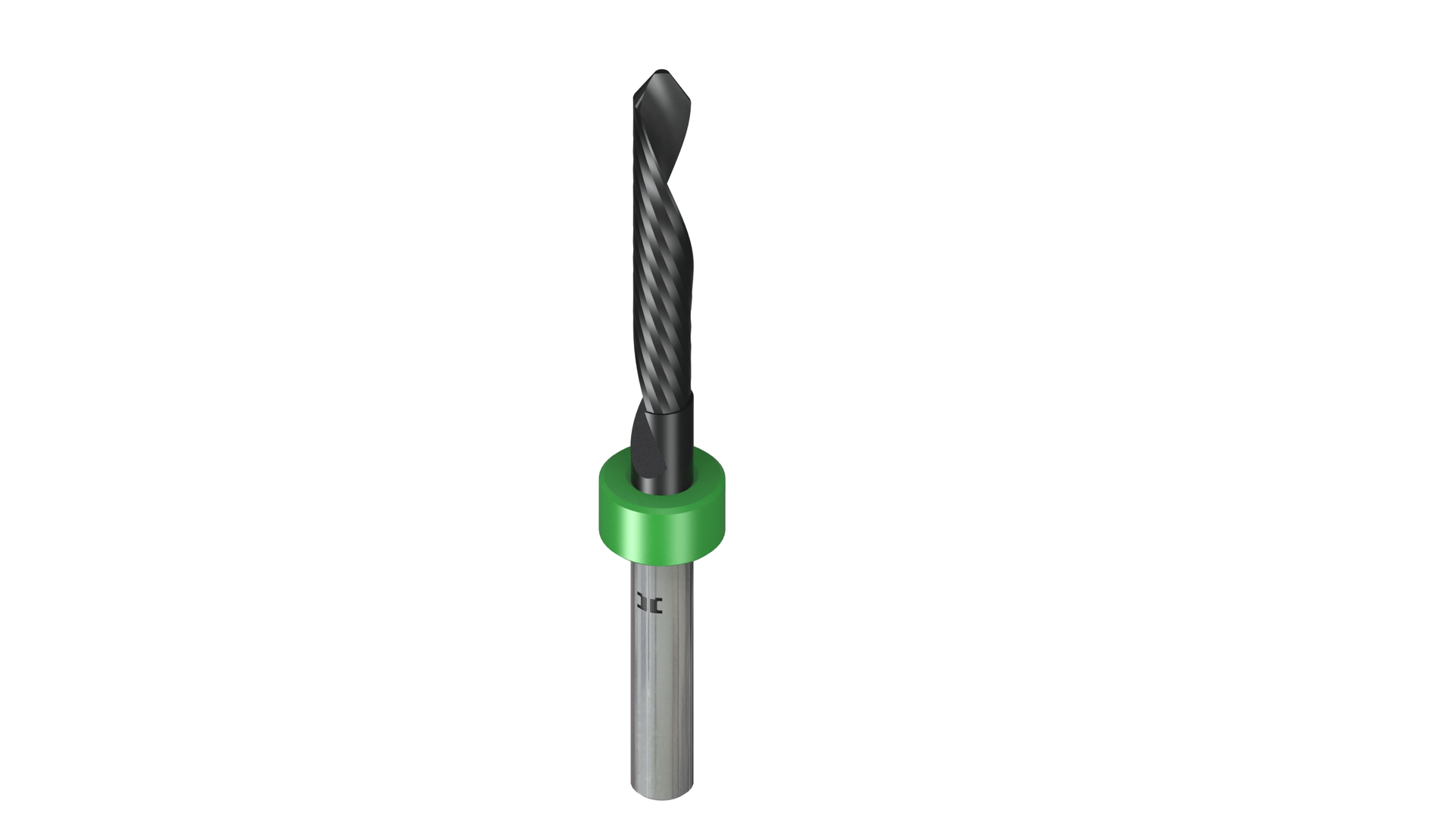

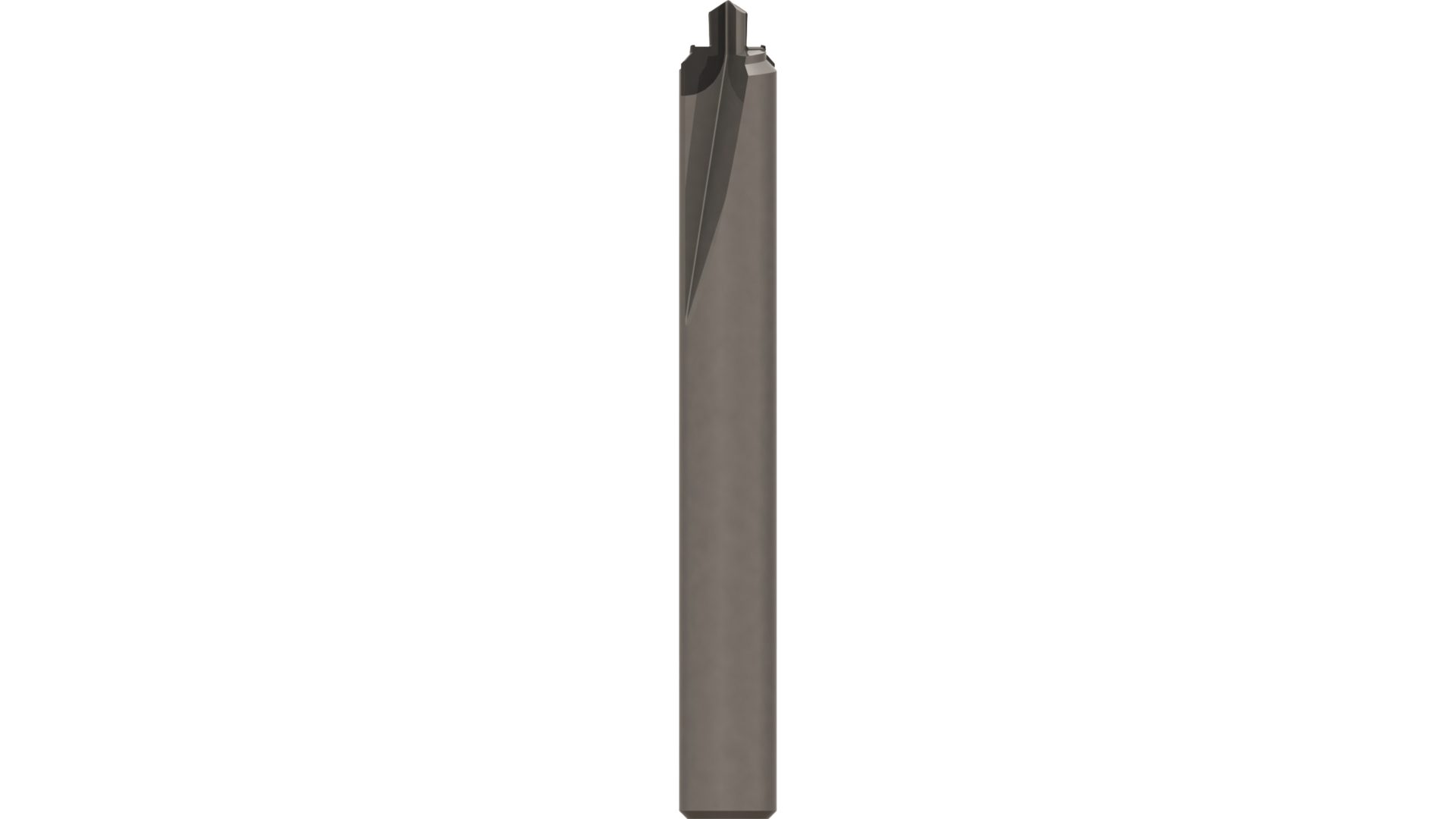

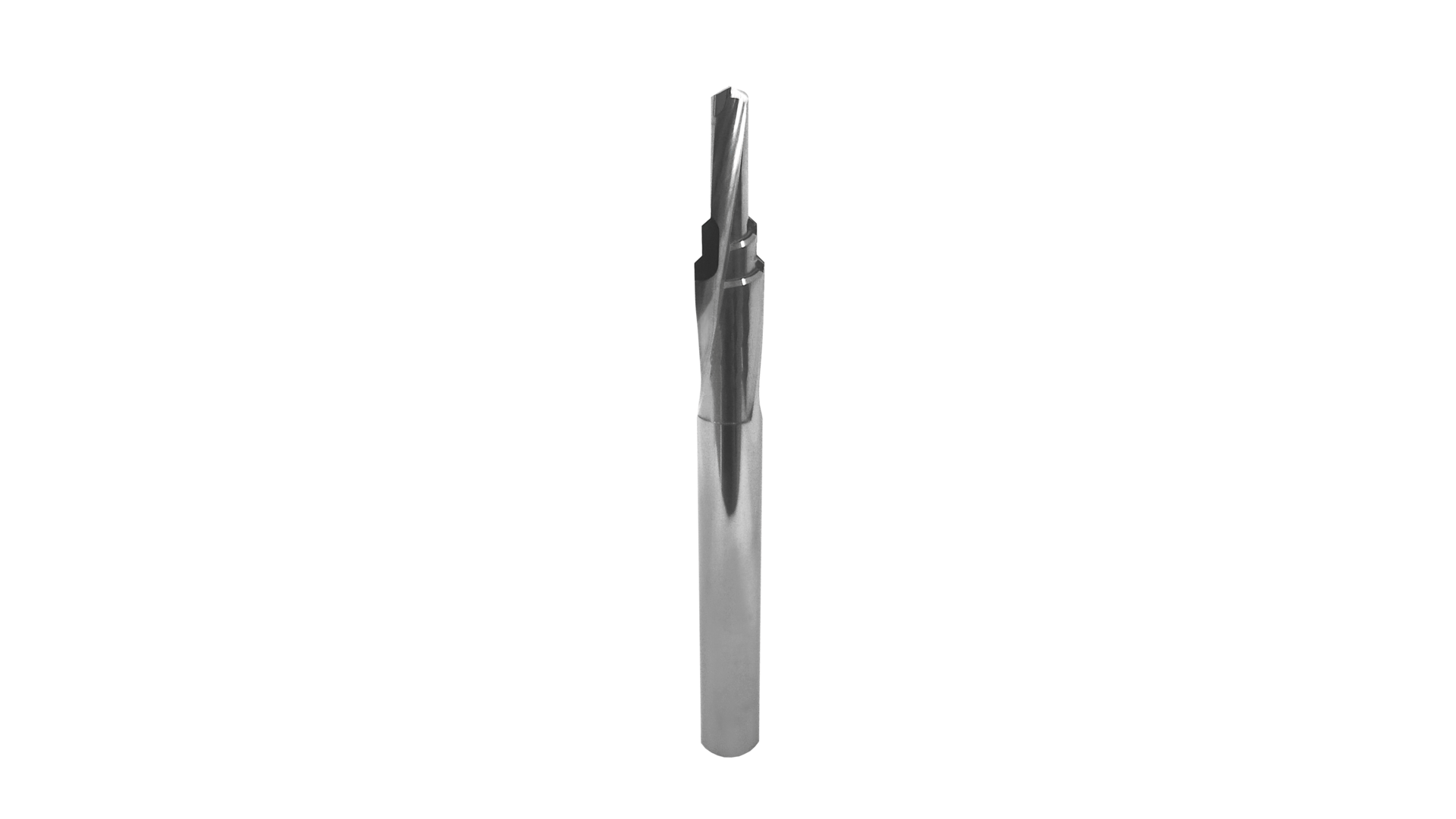

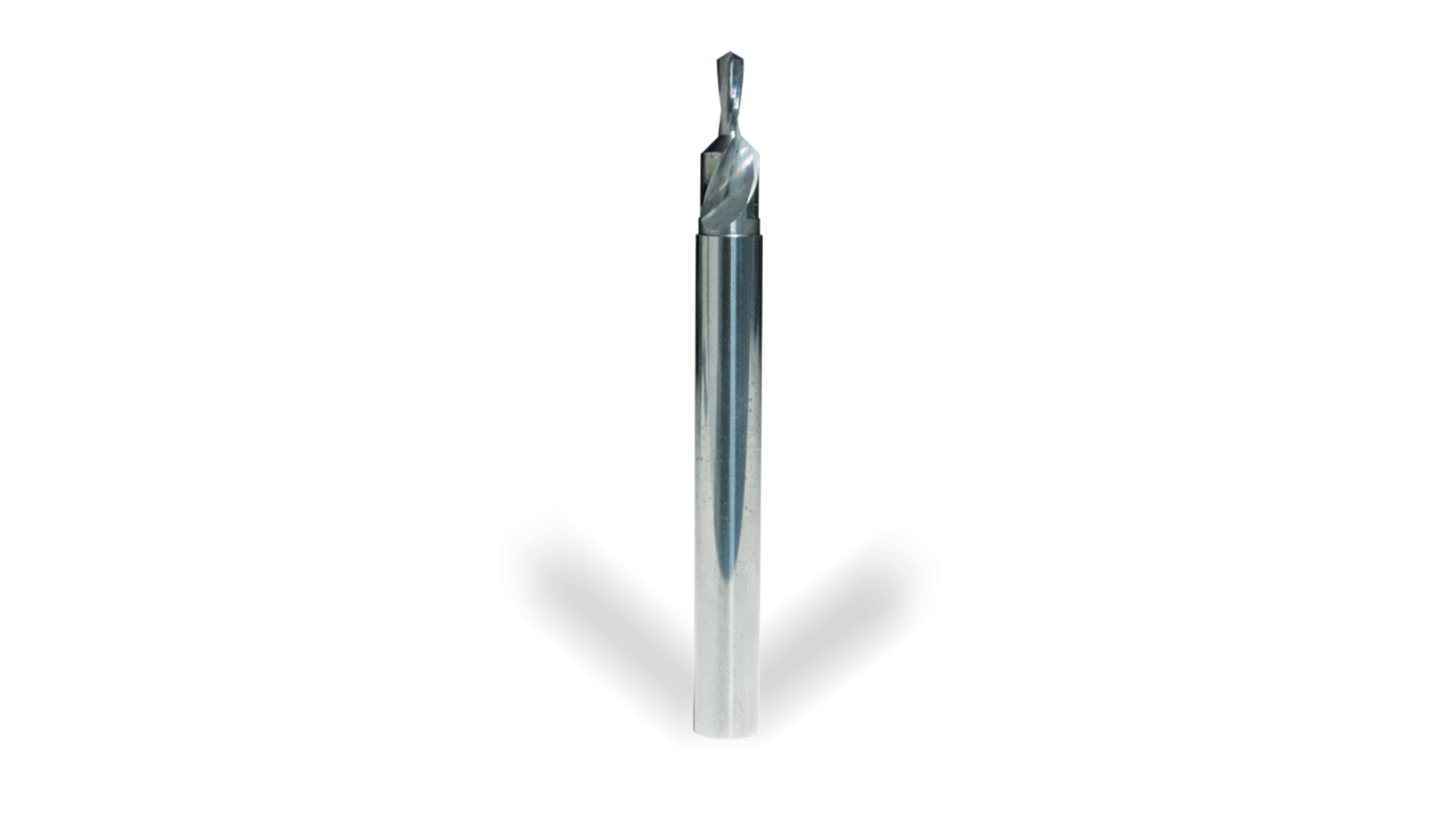

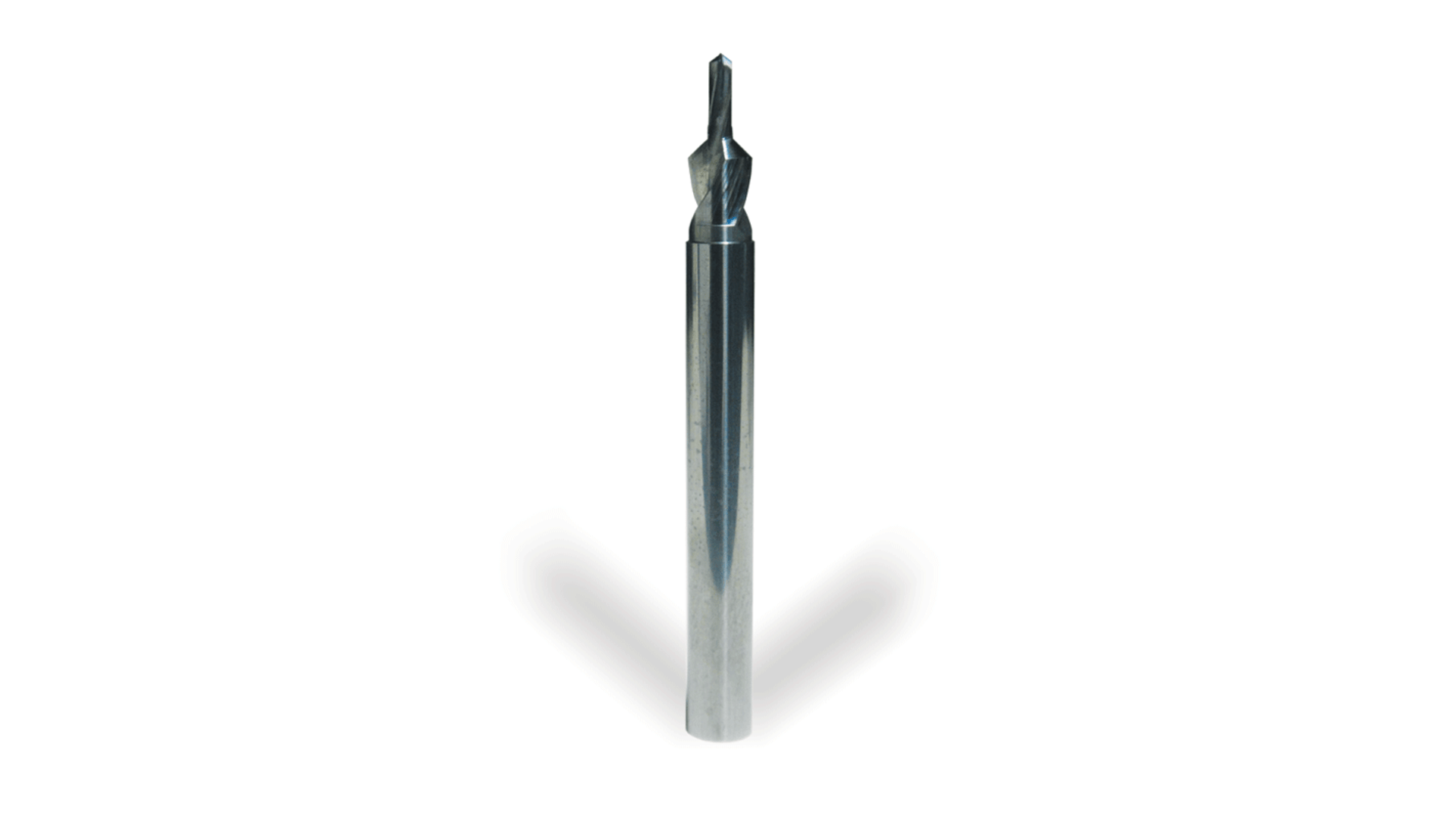

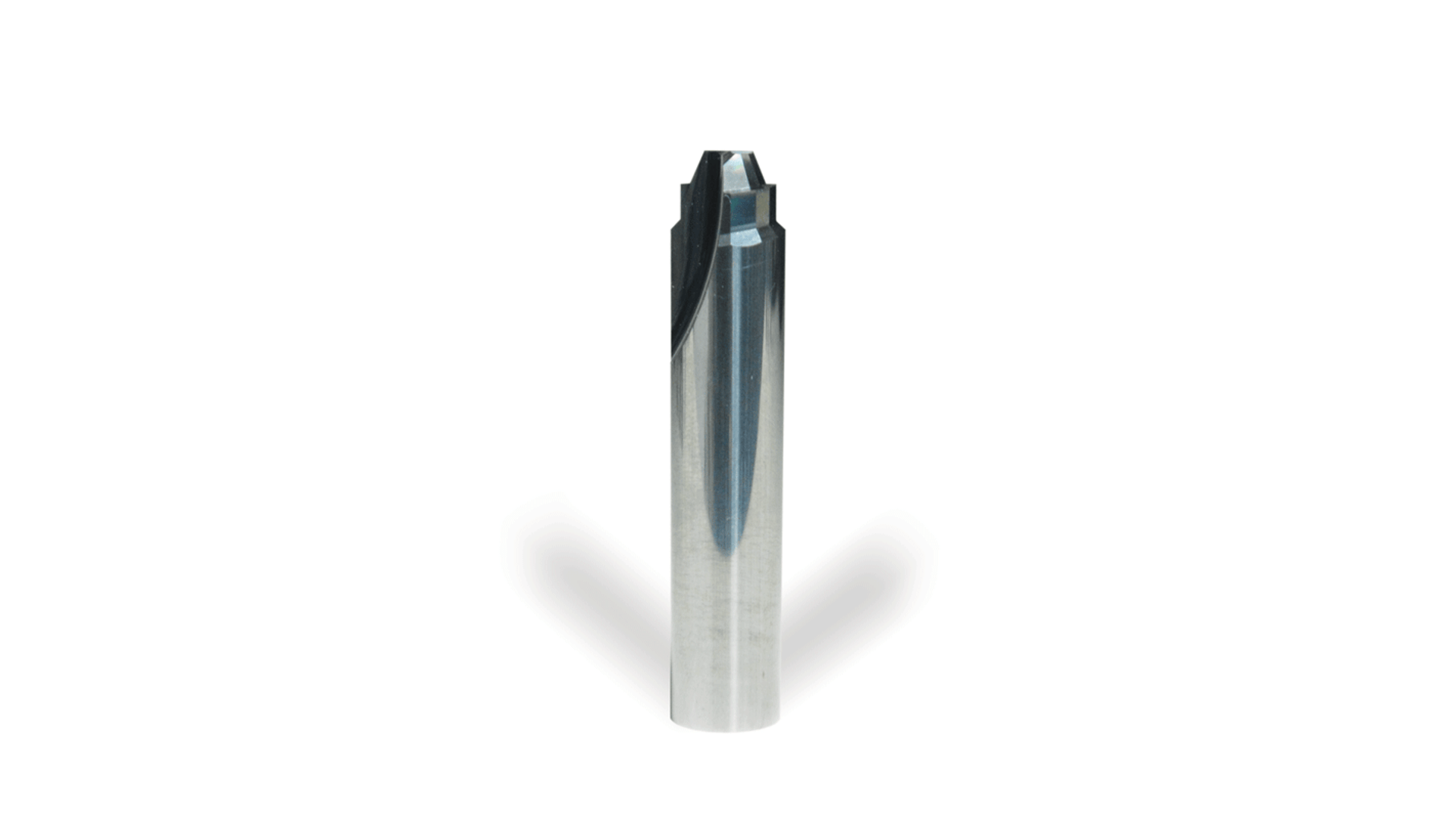

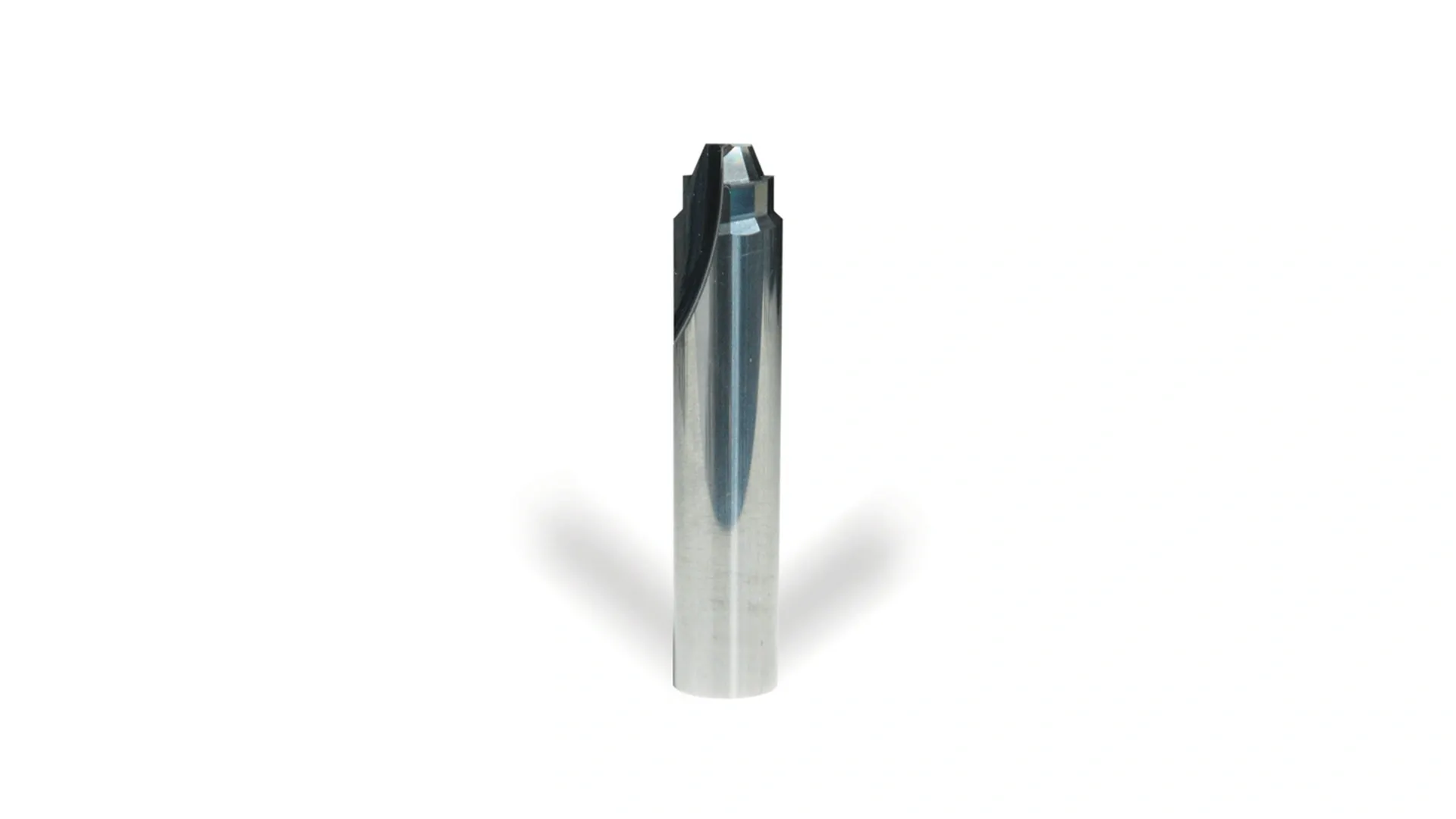

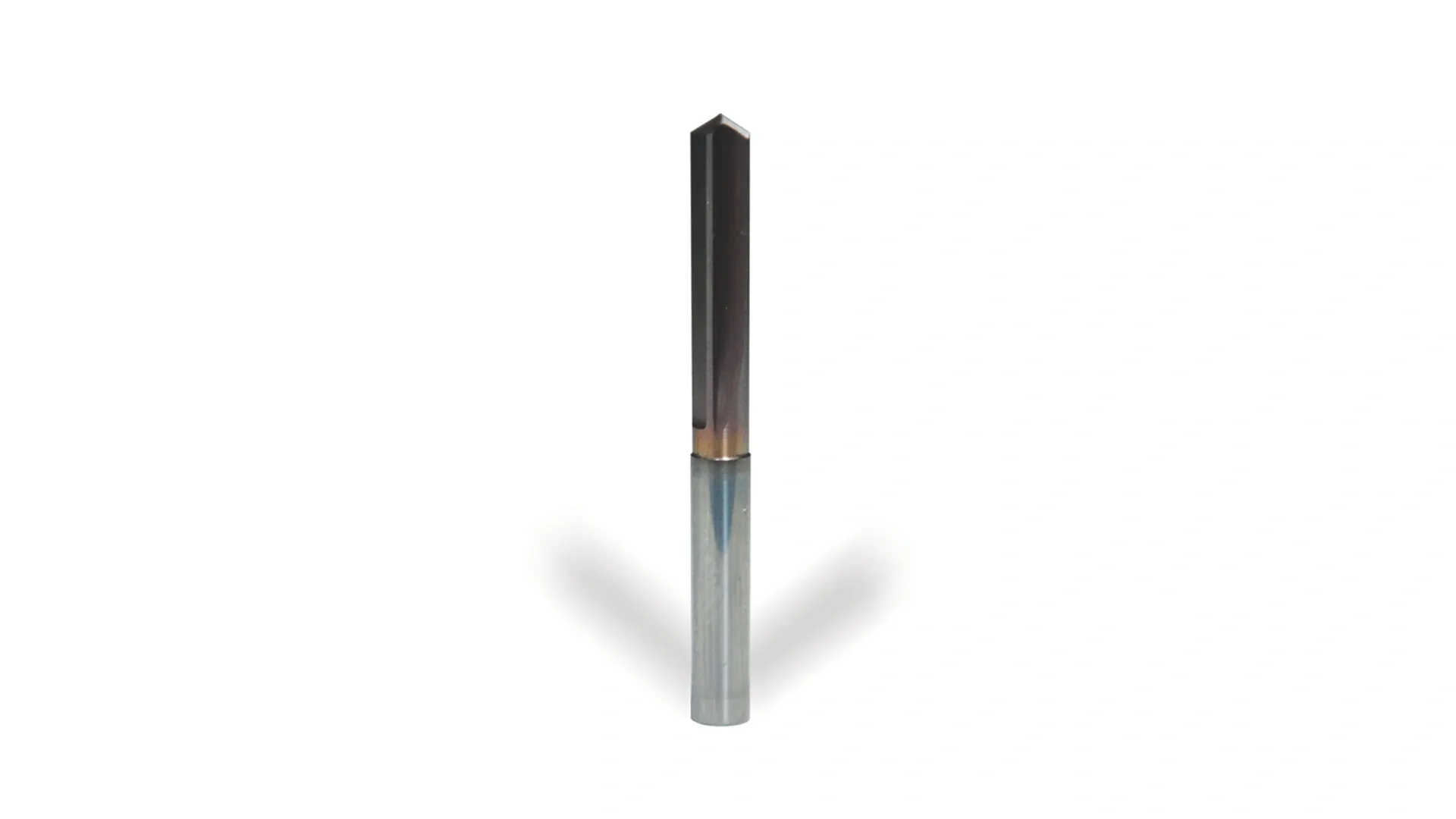

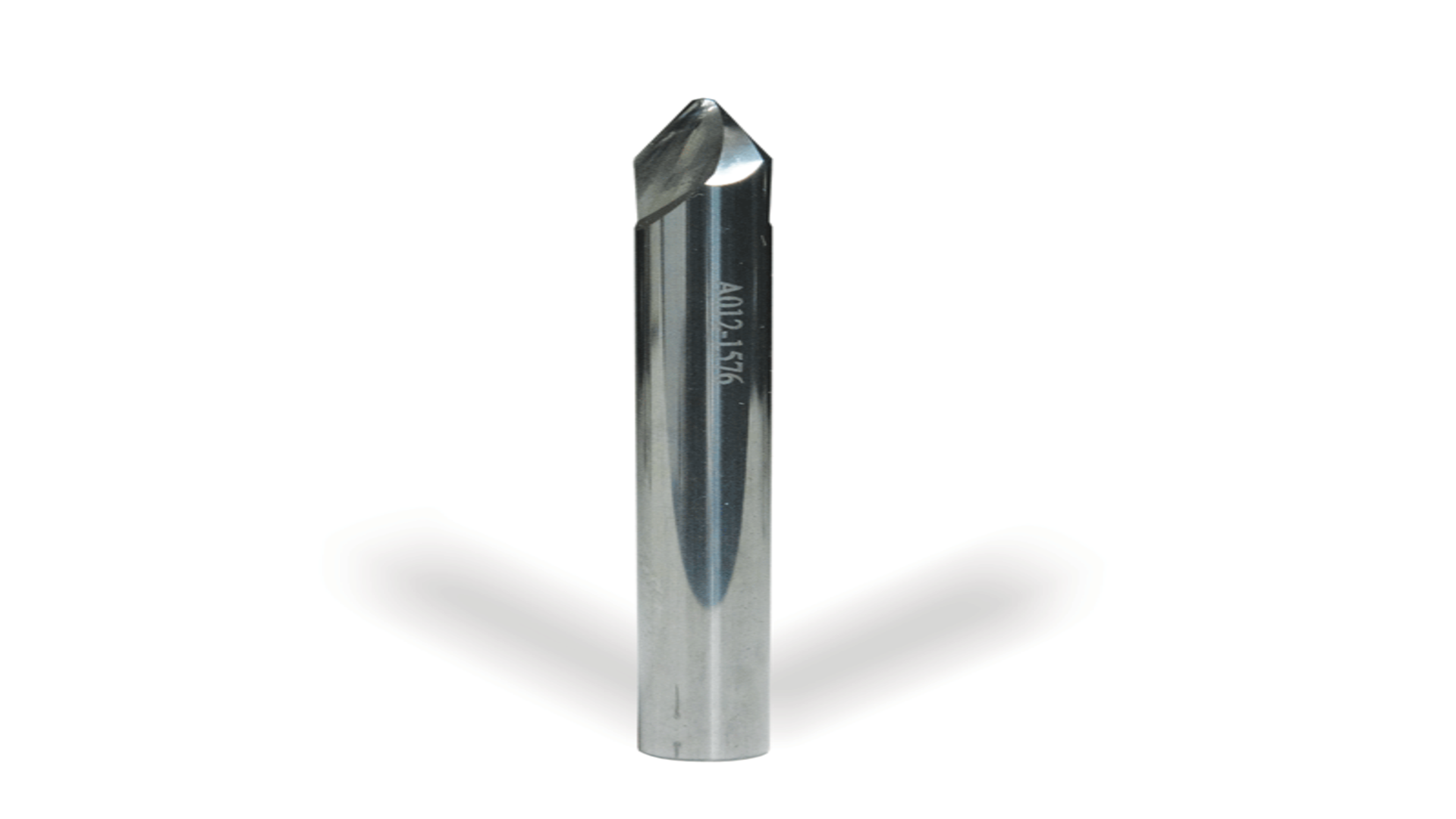

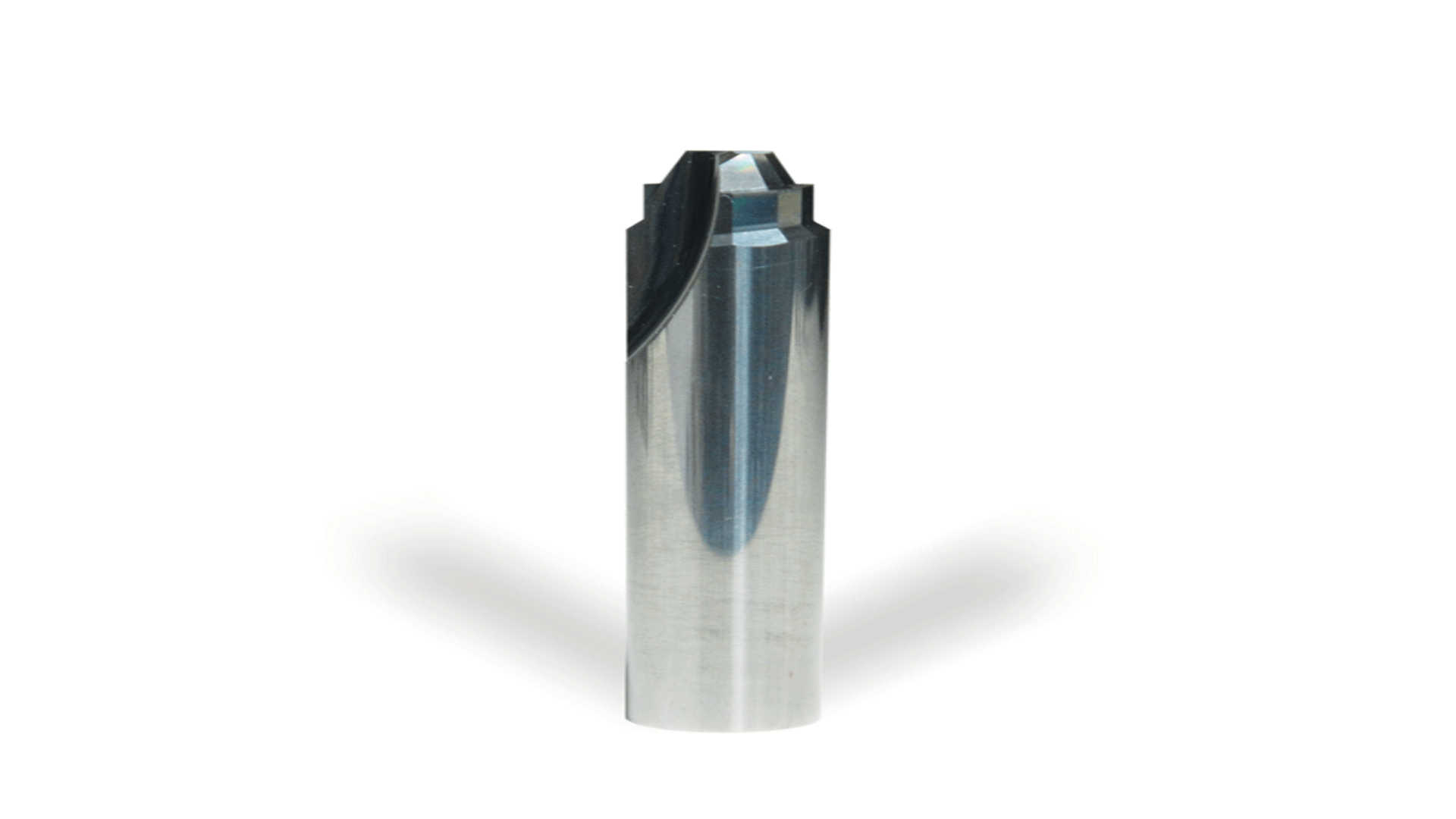

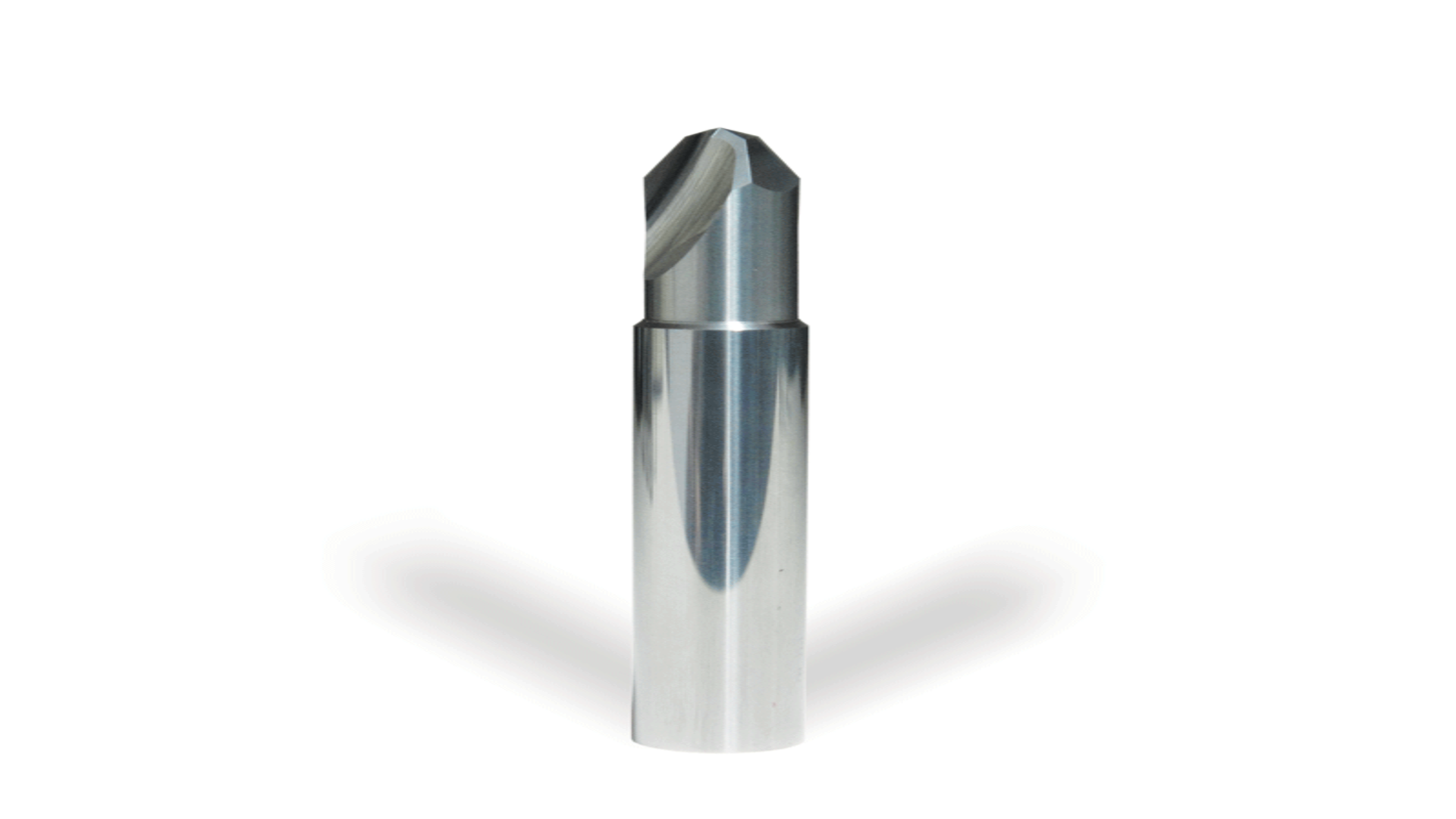

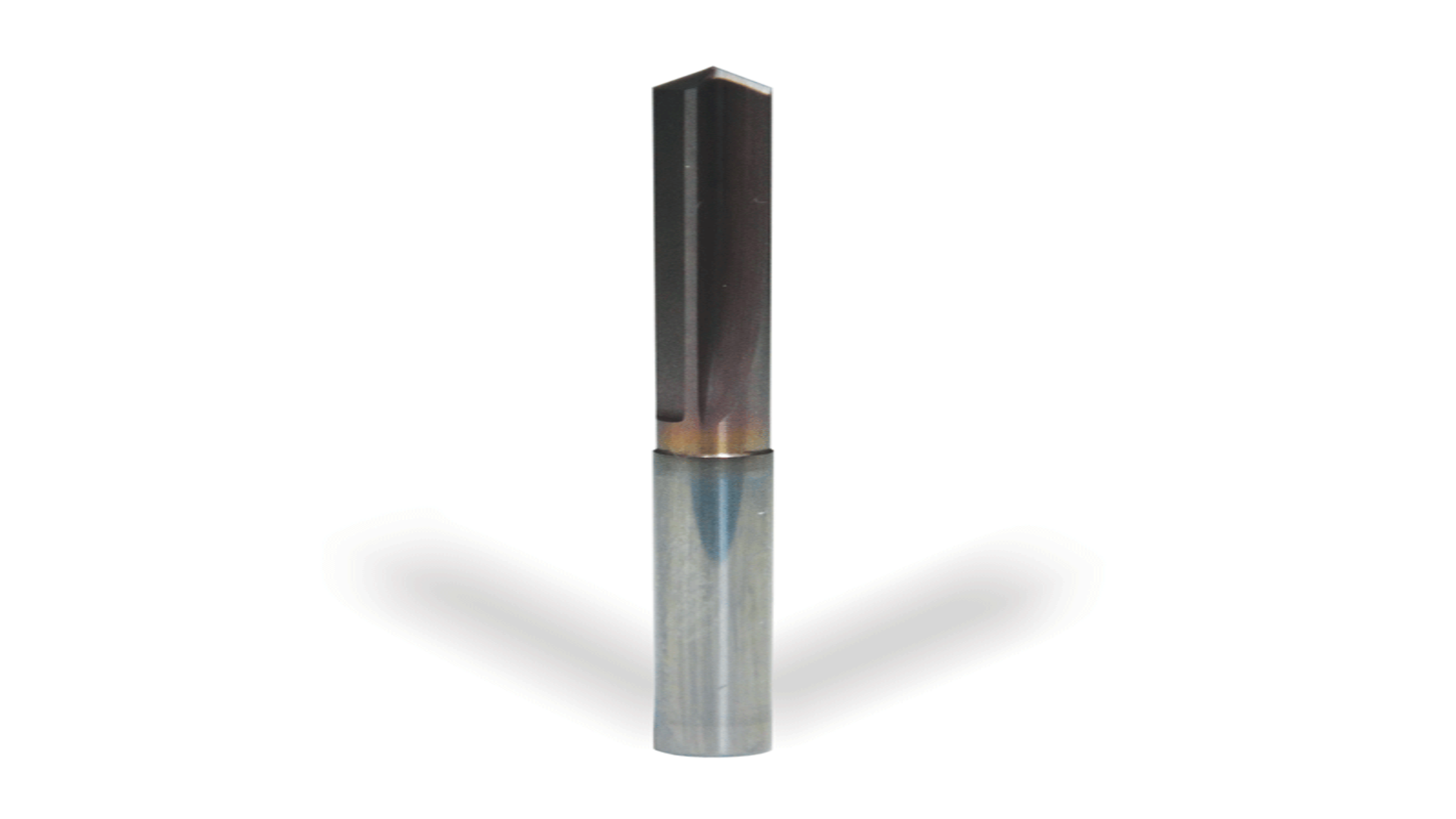

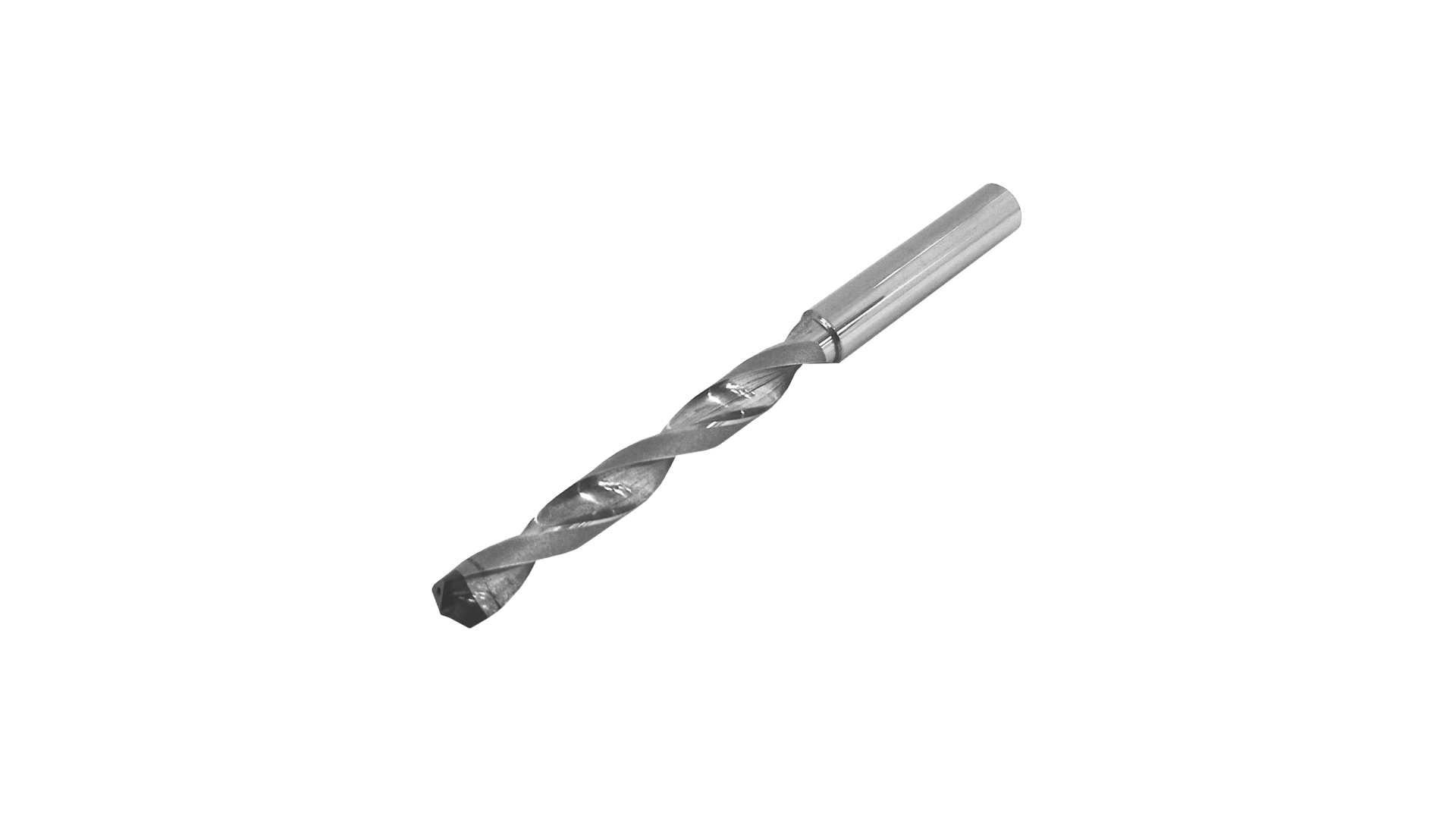

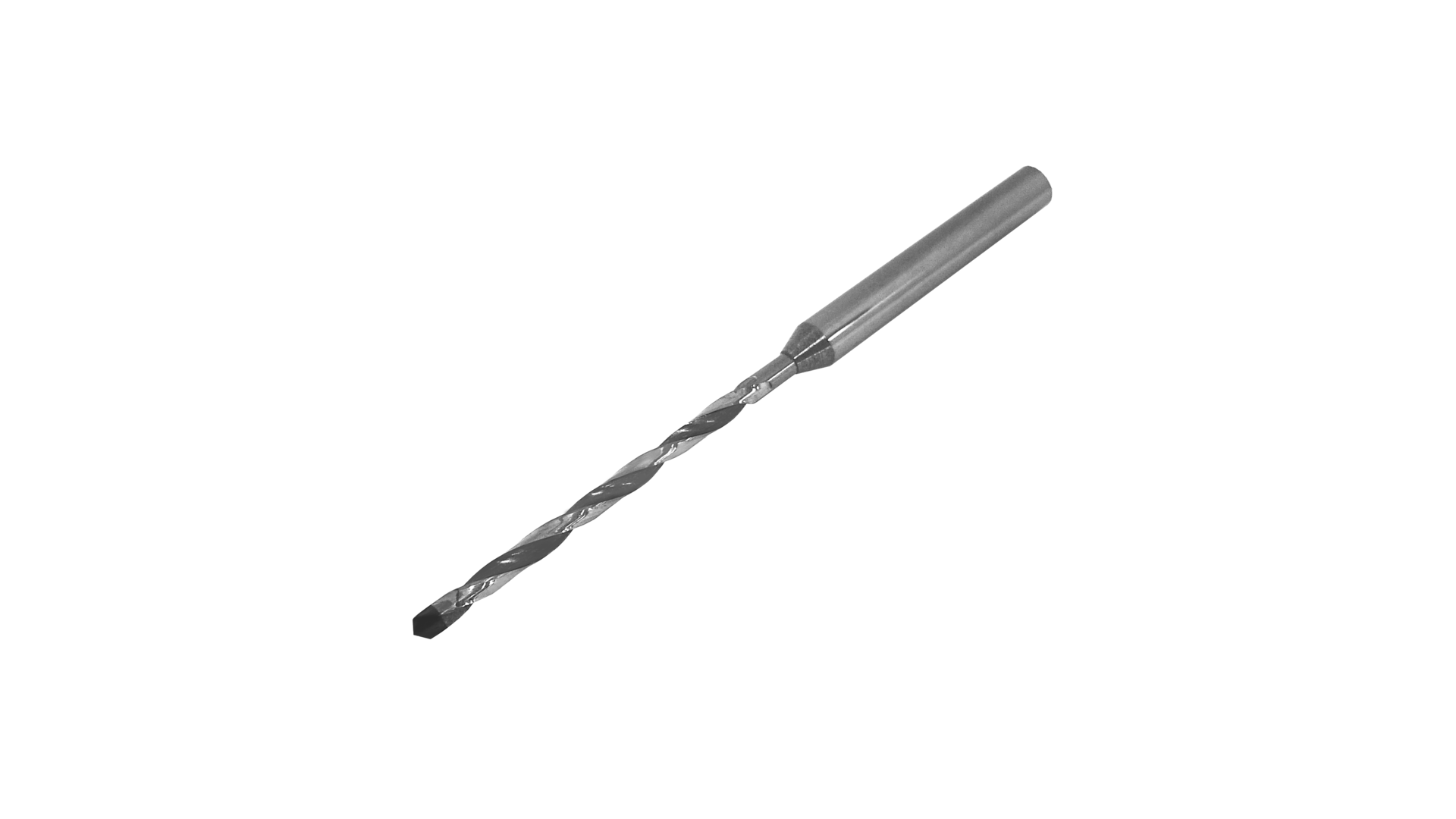

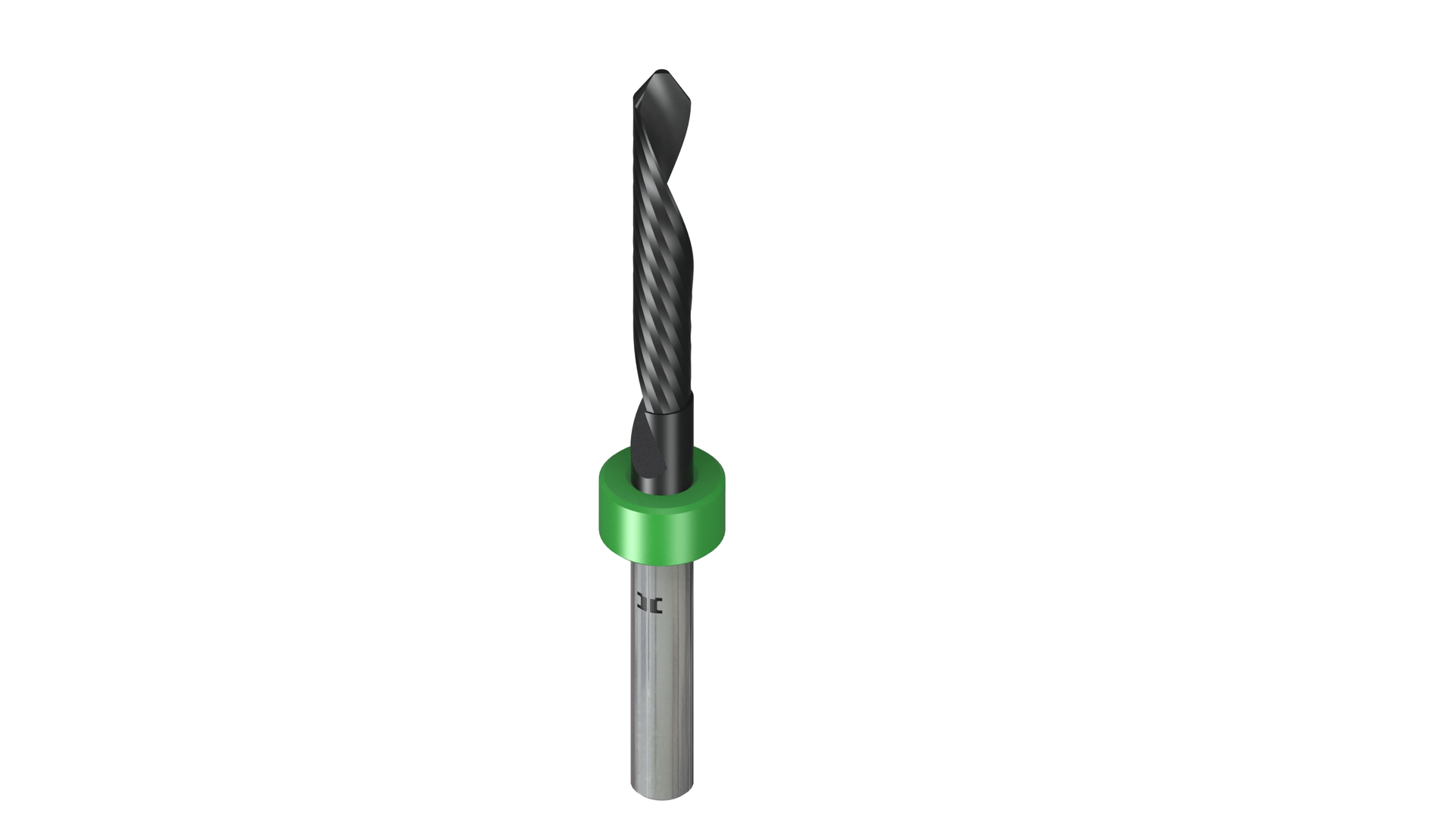

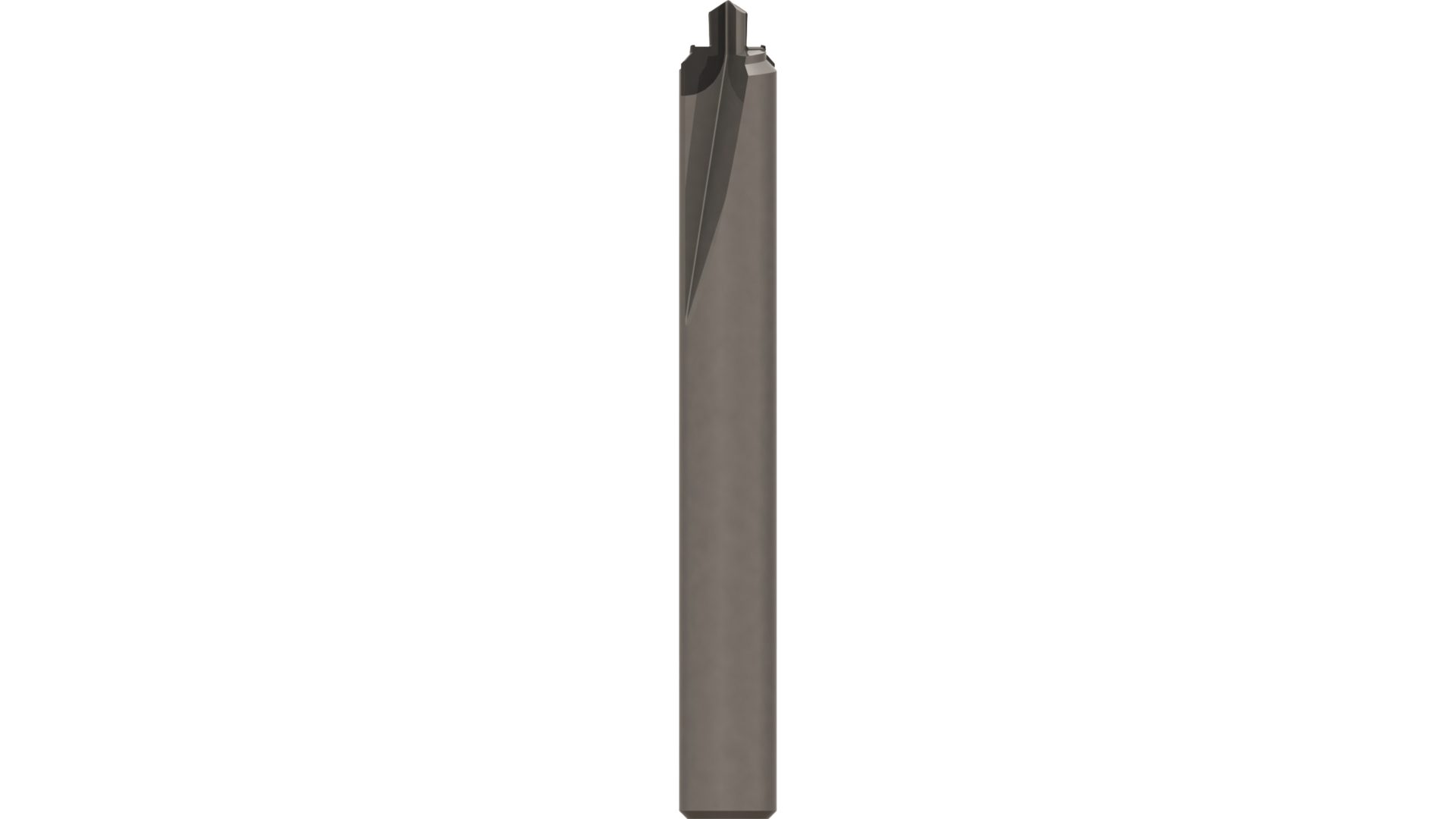

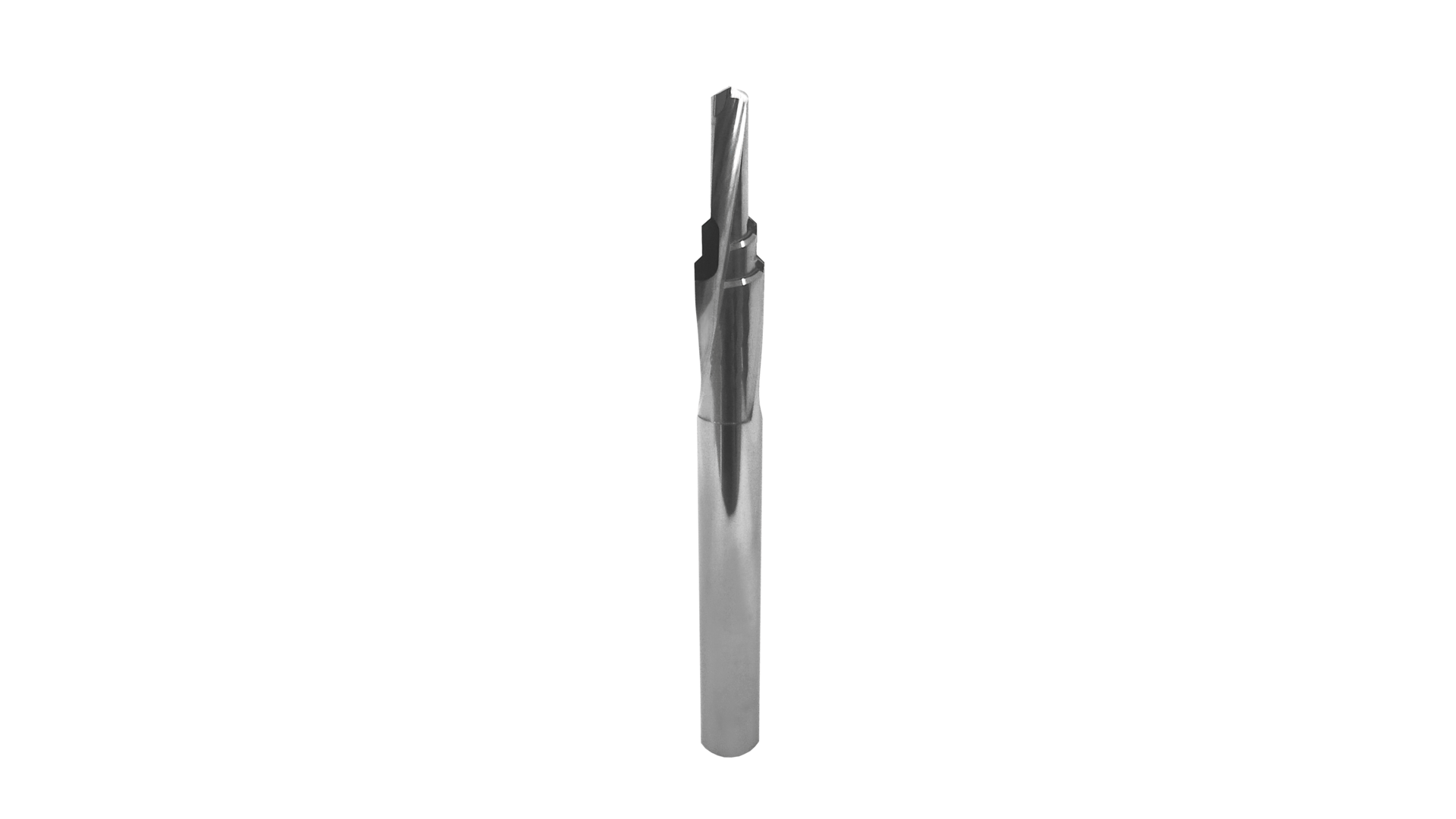

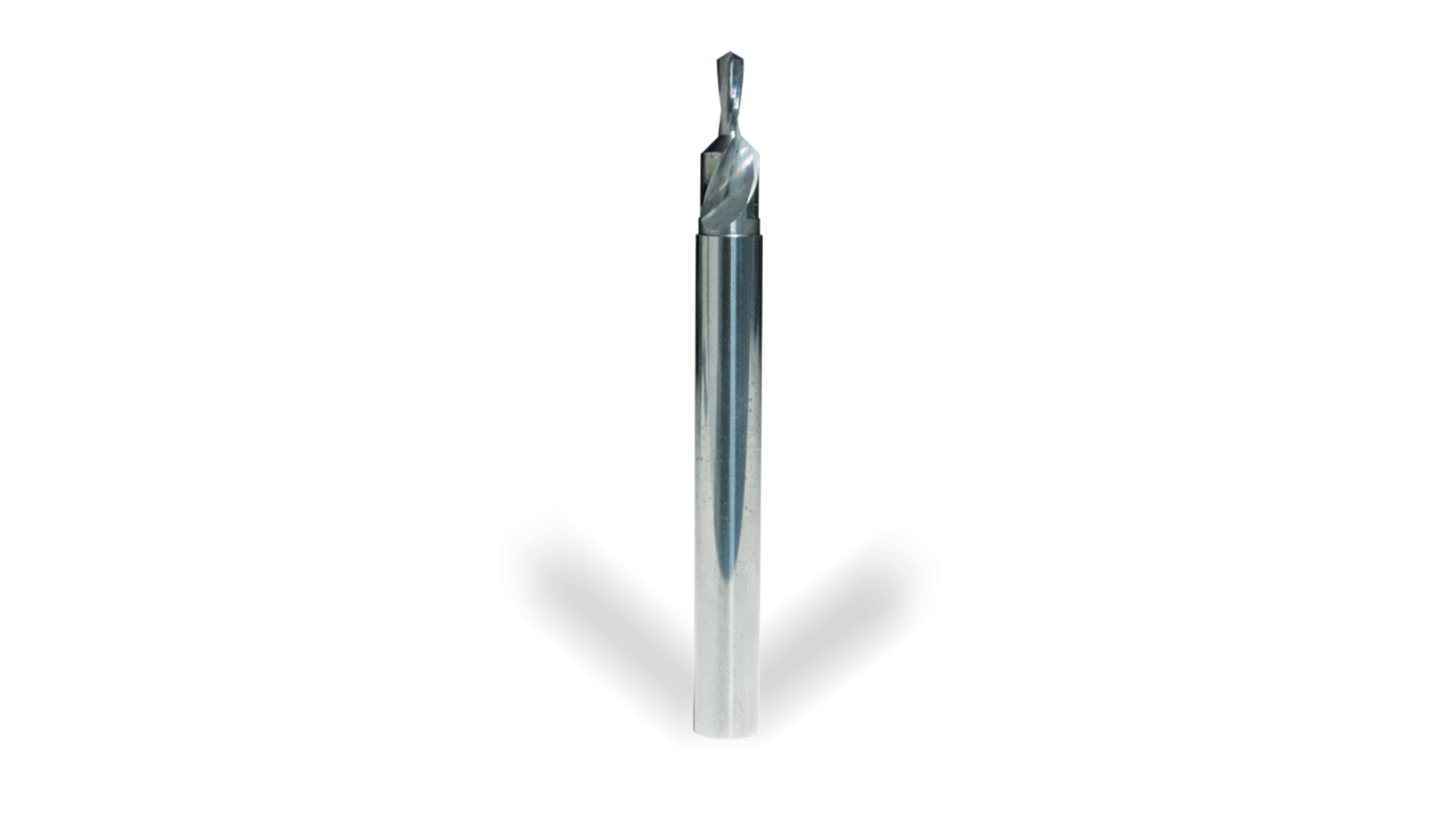

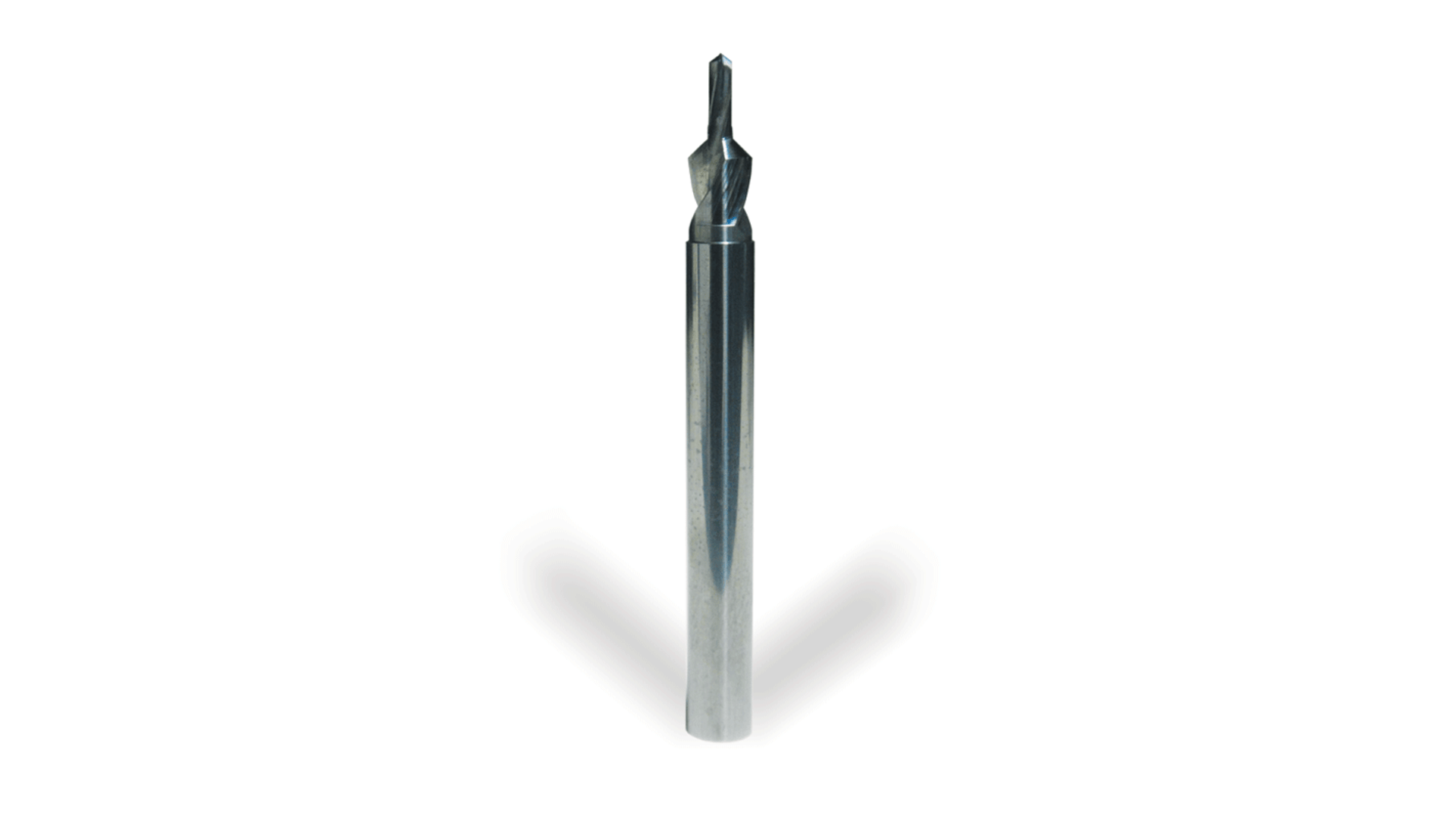

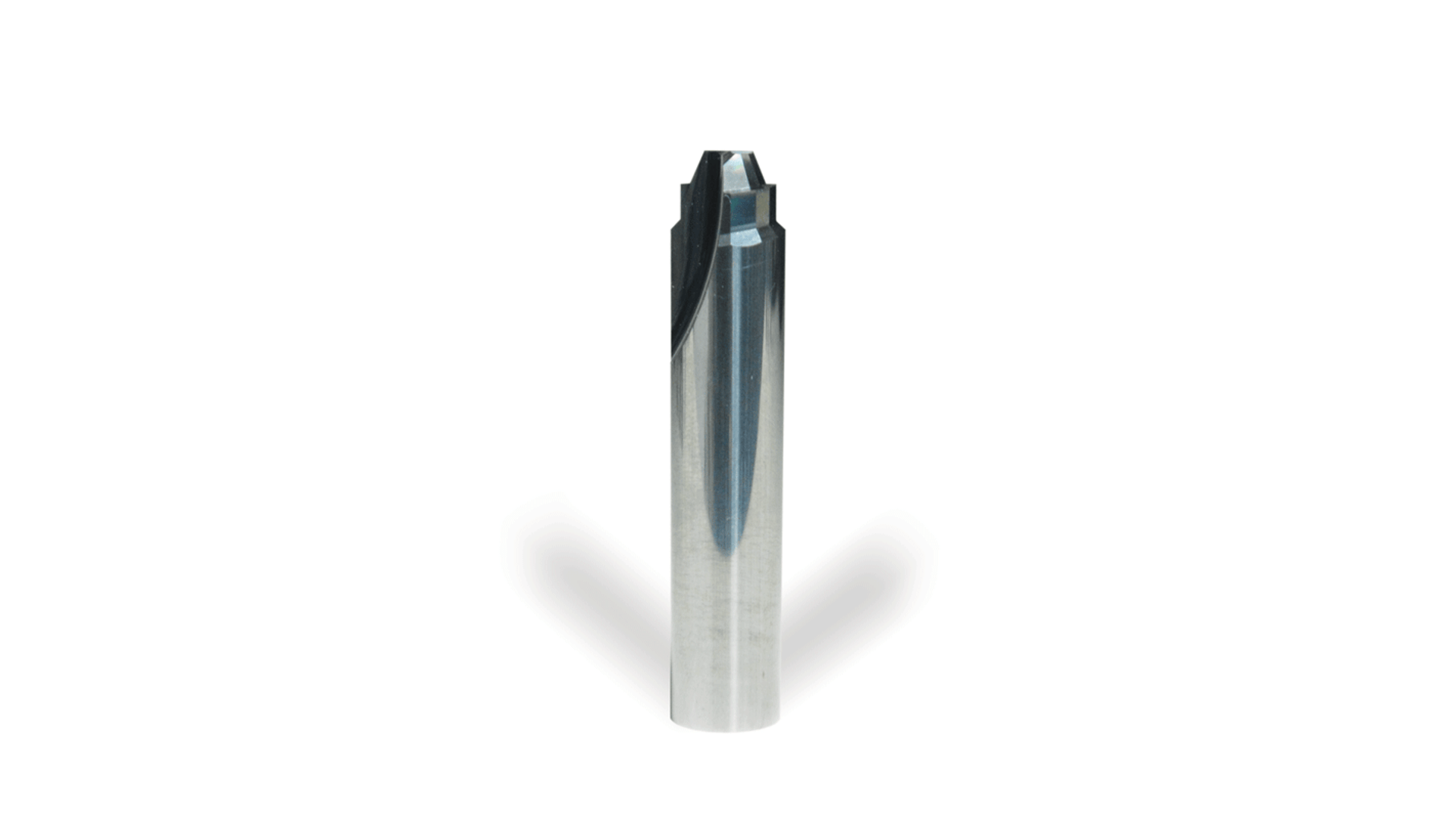

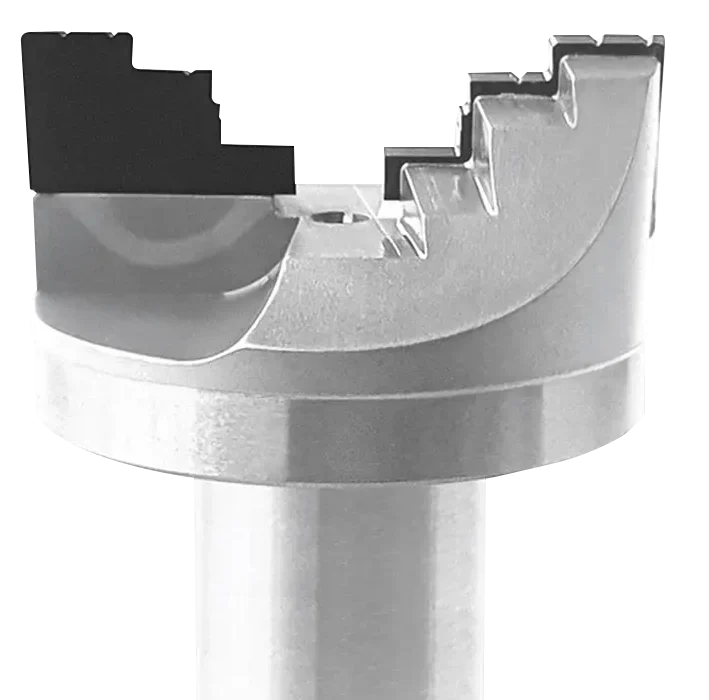

Polycrystaline diamond (PCD) drill is a high-performance cutting tool. The cutting edge is made from synthetic diamond. It is suitable for cutting non-ferrous materials such as aluminum alloys, copper, brass, glass, wood, ceramics, plastics, fiberglass composites, carbon fiber composites (CFRP), as well as many metal matrix composites (MMC).

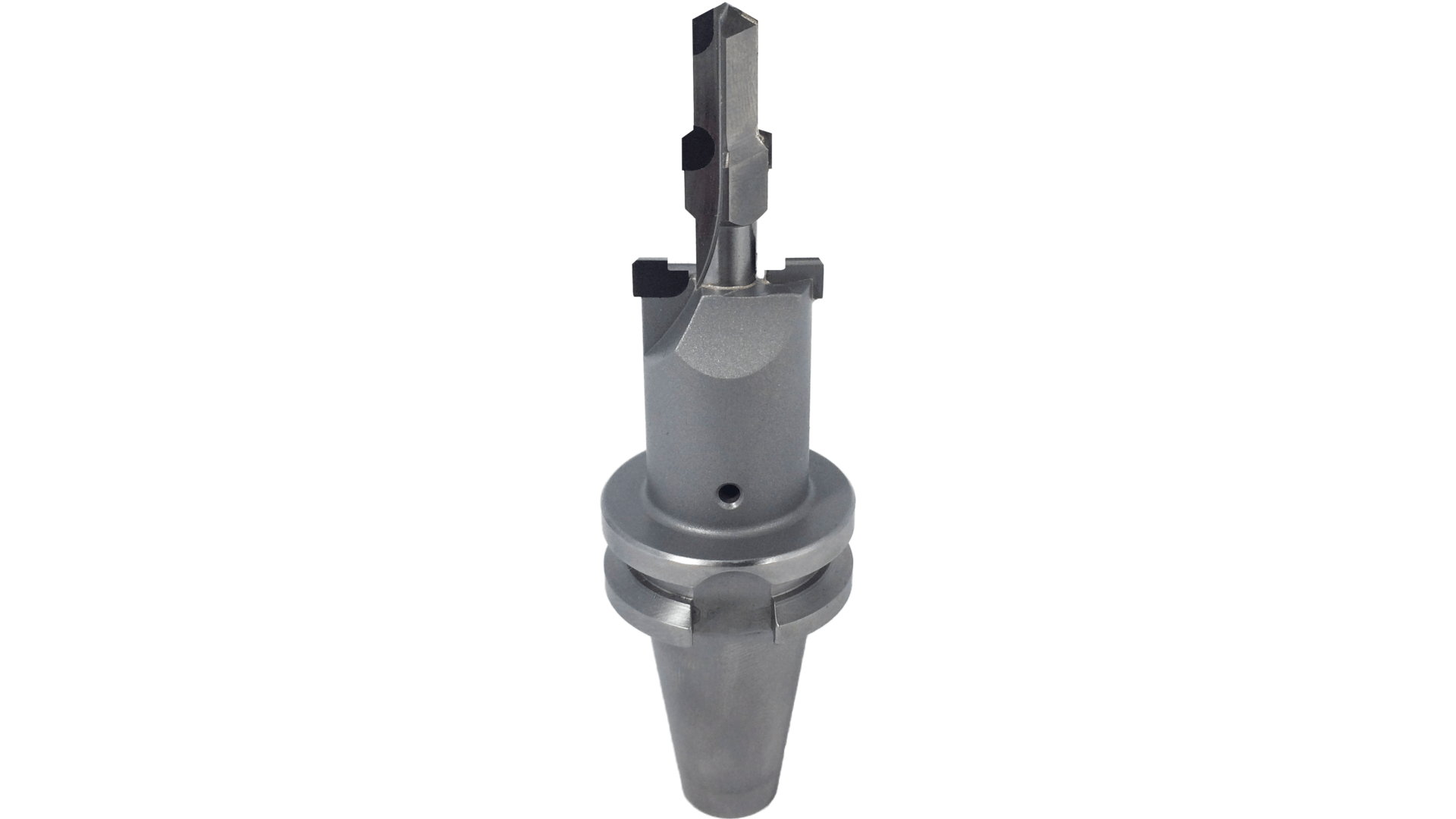

Halcyon specializes in designing and manufacturing special PCD drills customized to perform best for your application. PCD center-cutting drill is available for the longest tool life possible. High helix angle is possible. Internal coolant hole is available for temperature control, as well as chip evacuation.