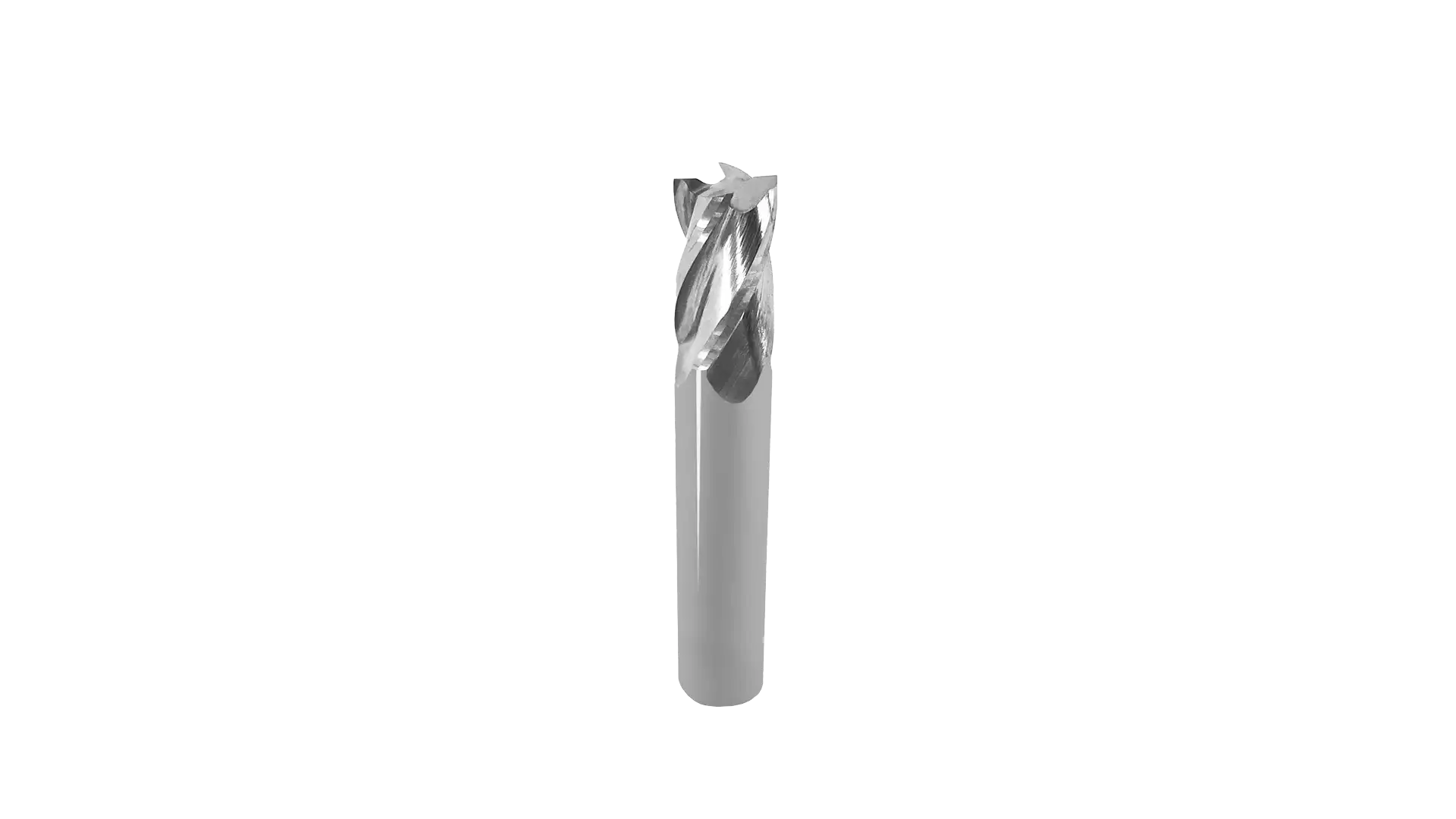

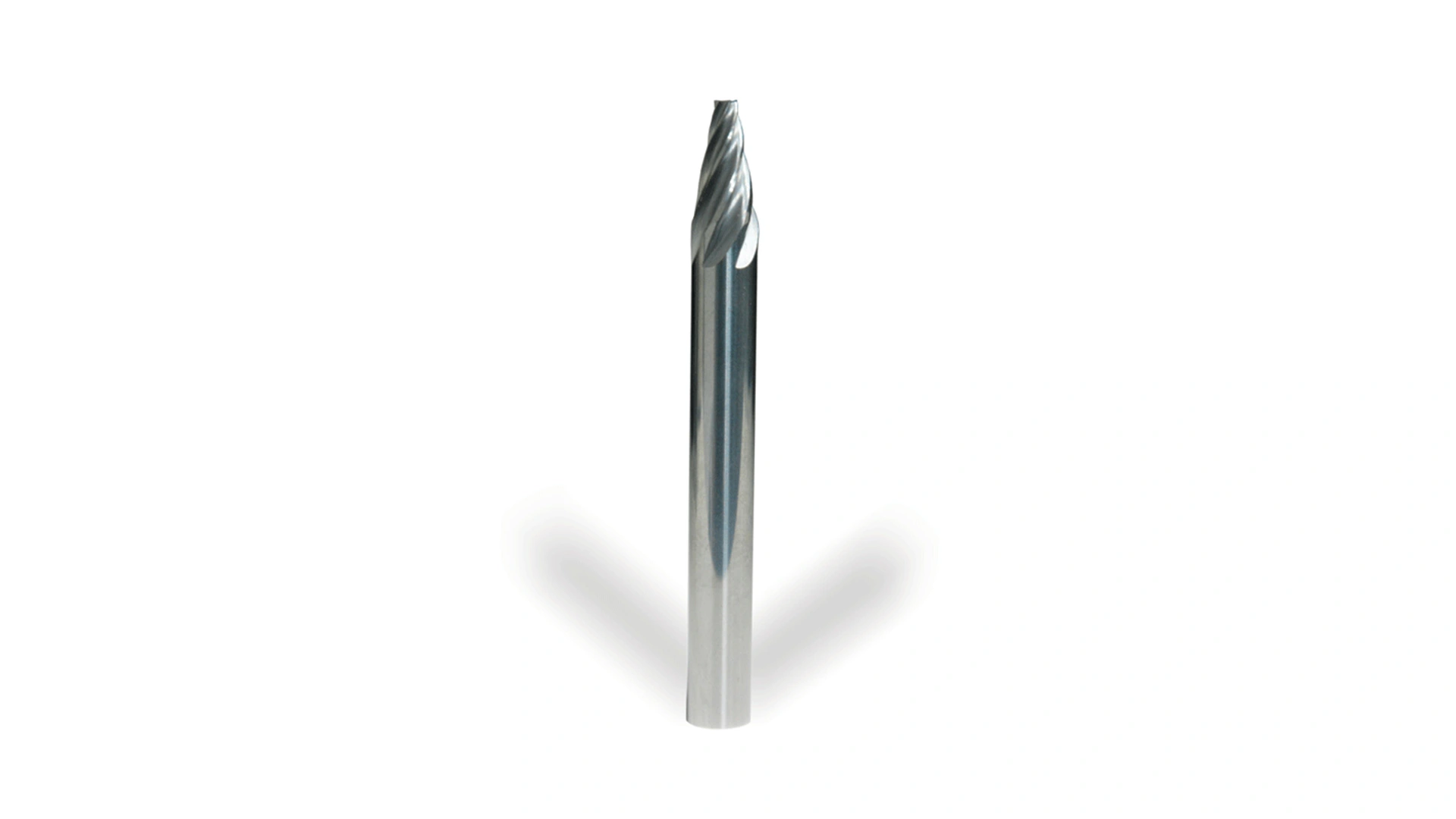

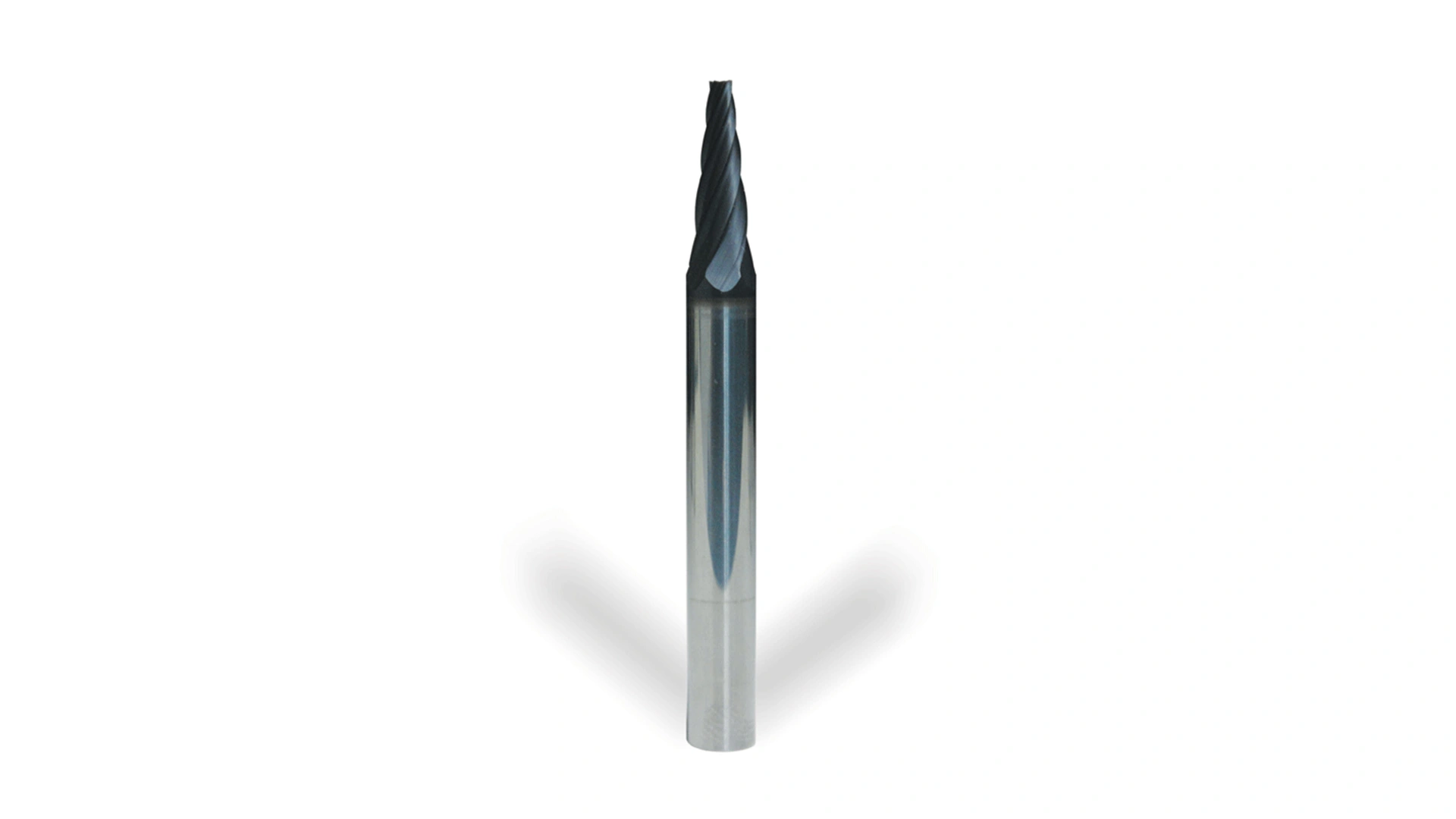

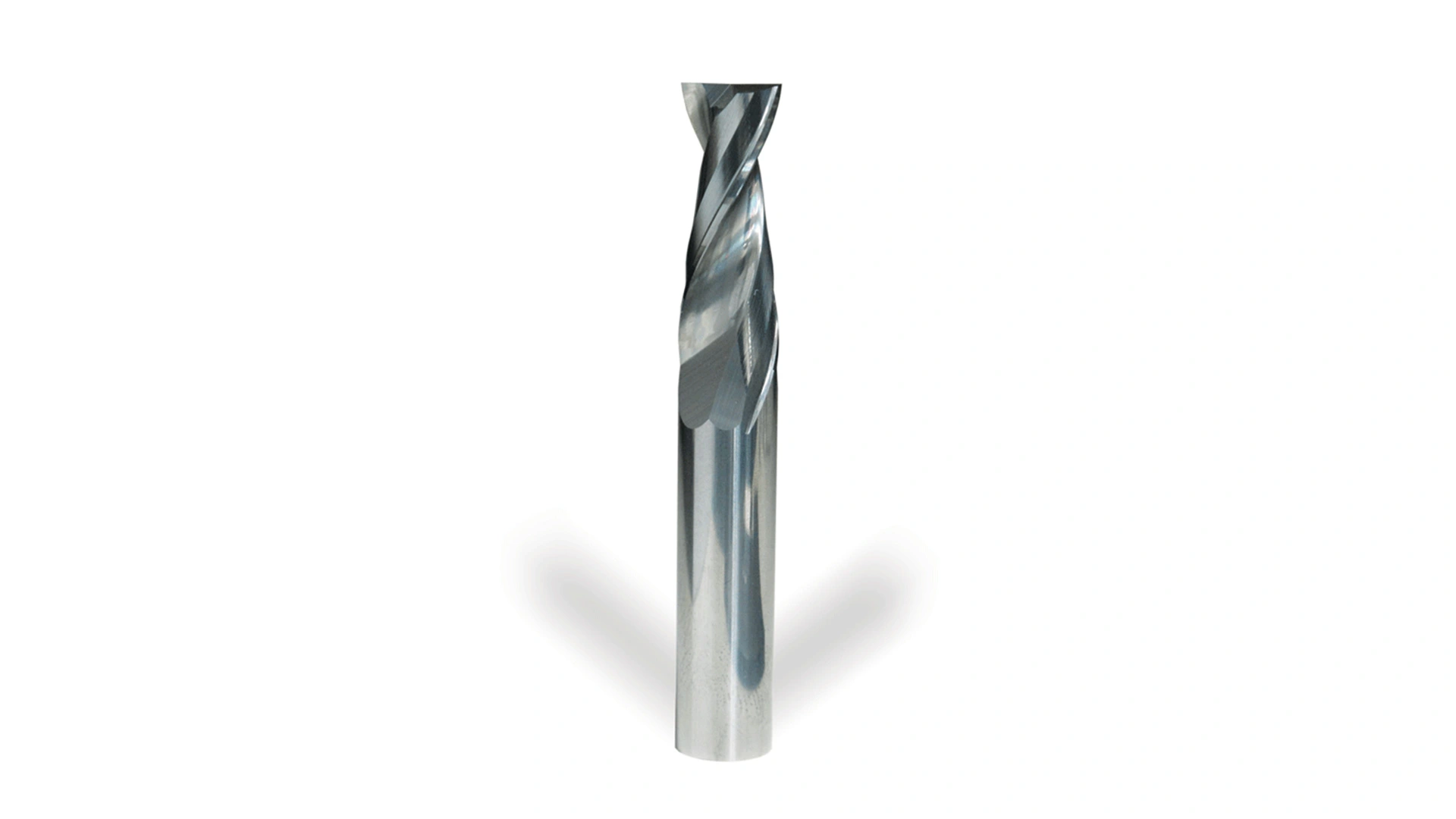

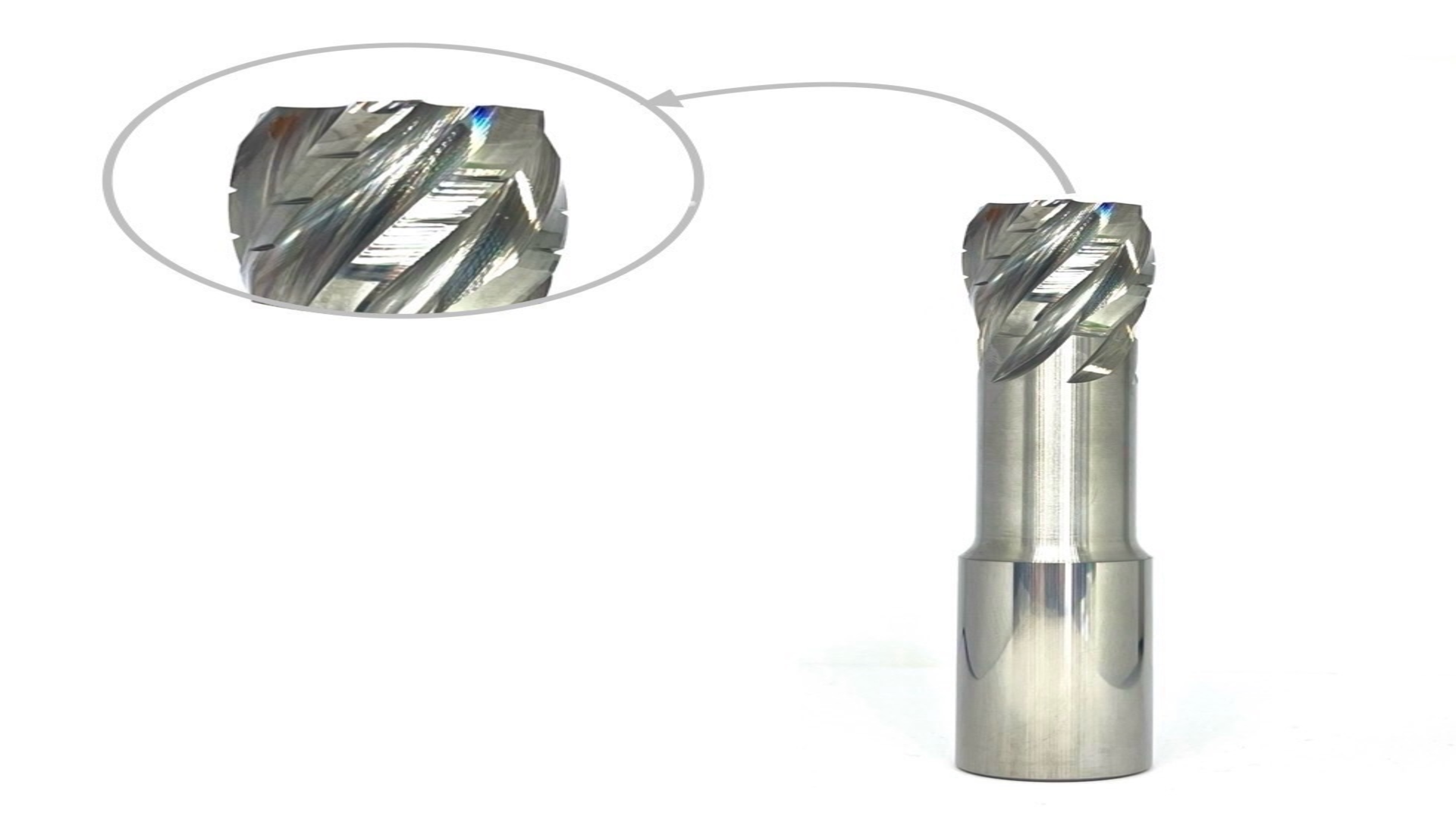

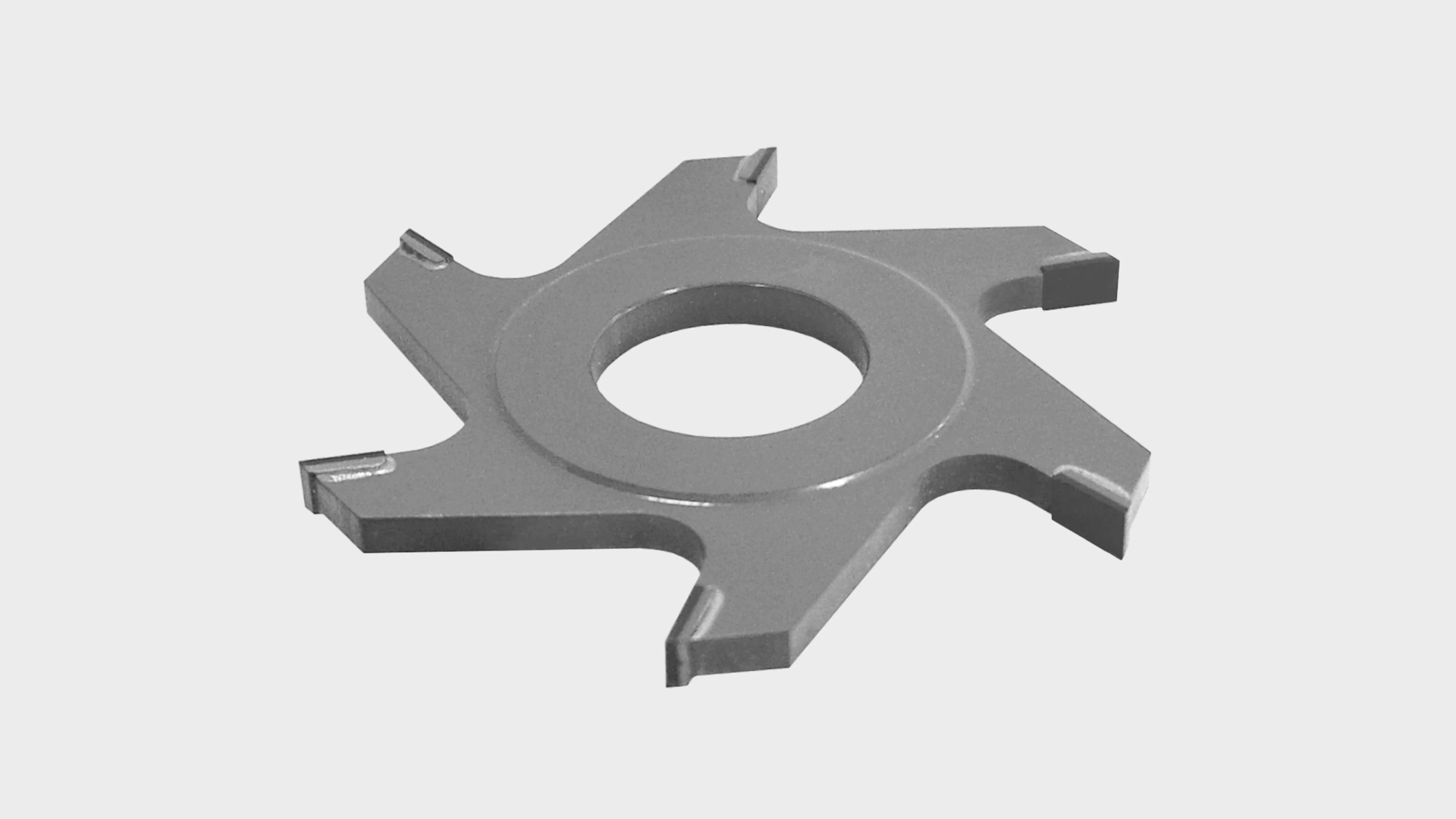

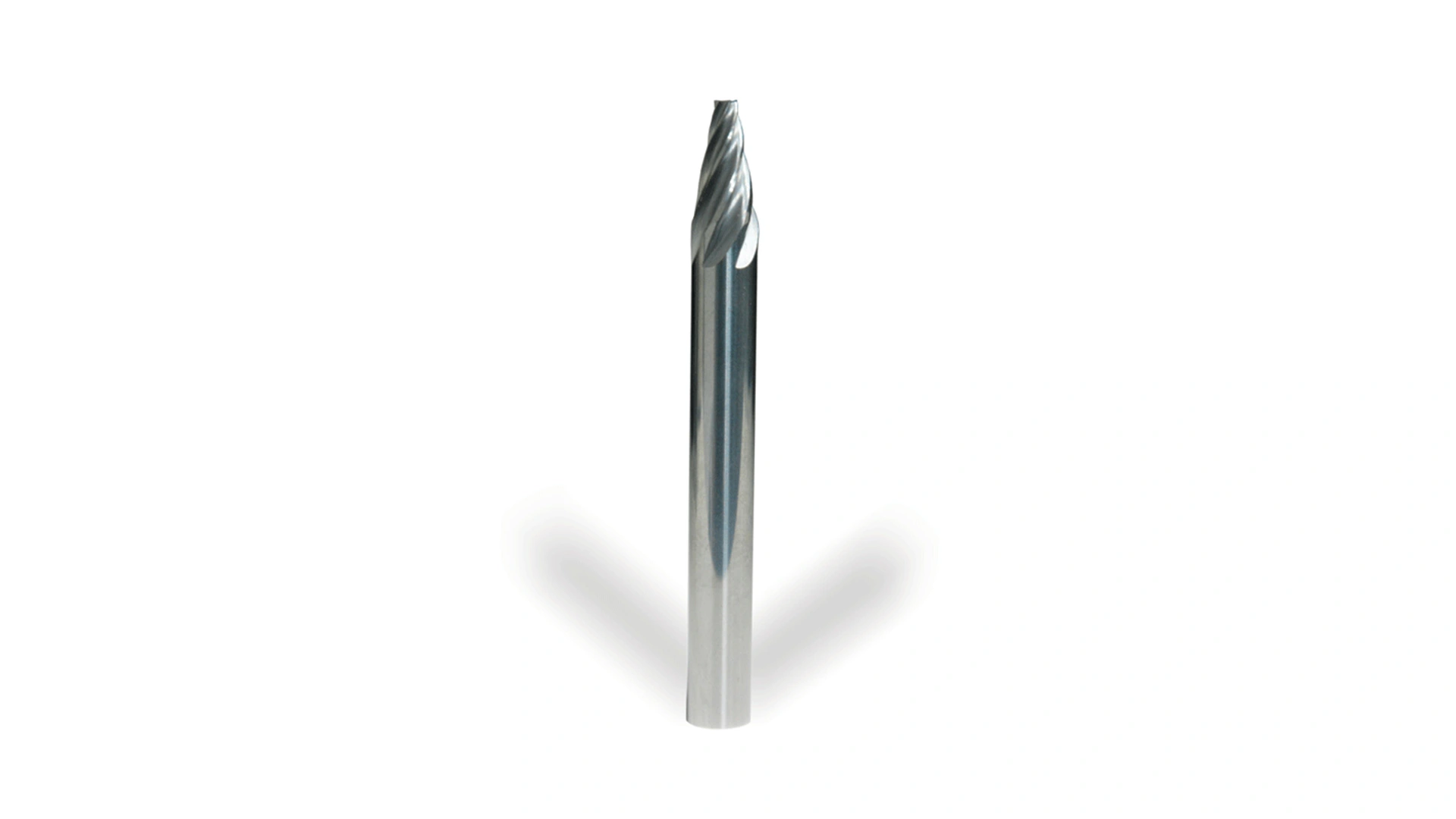

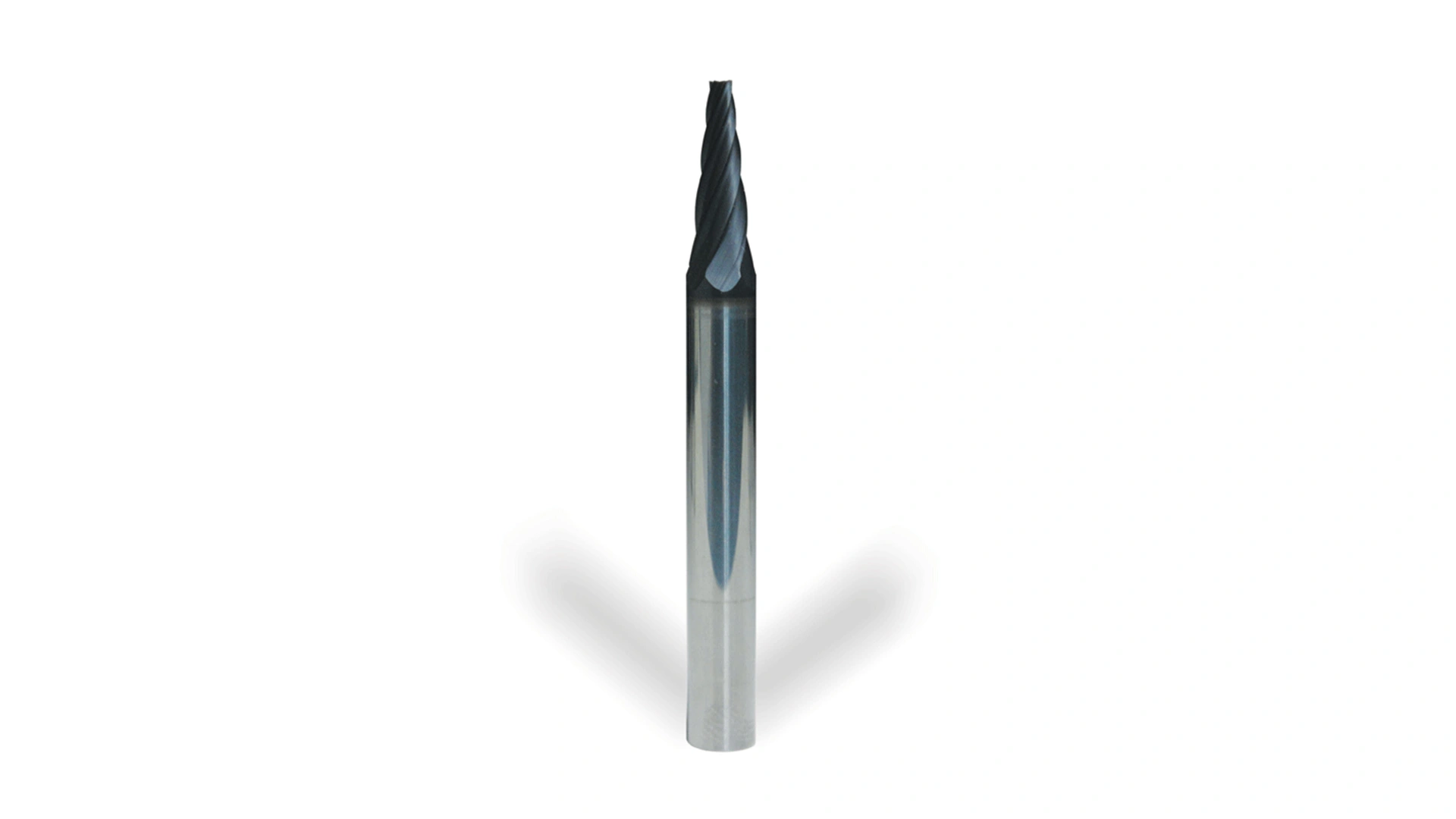

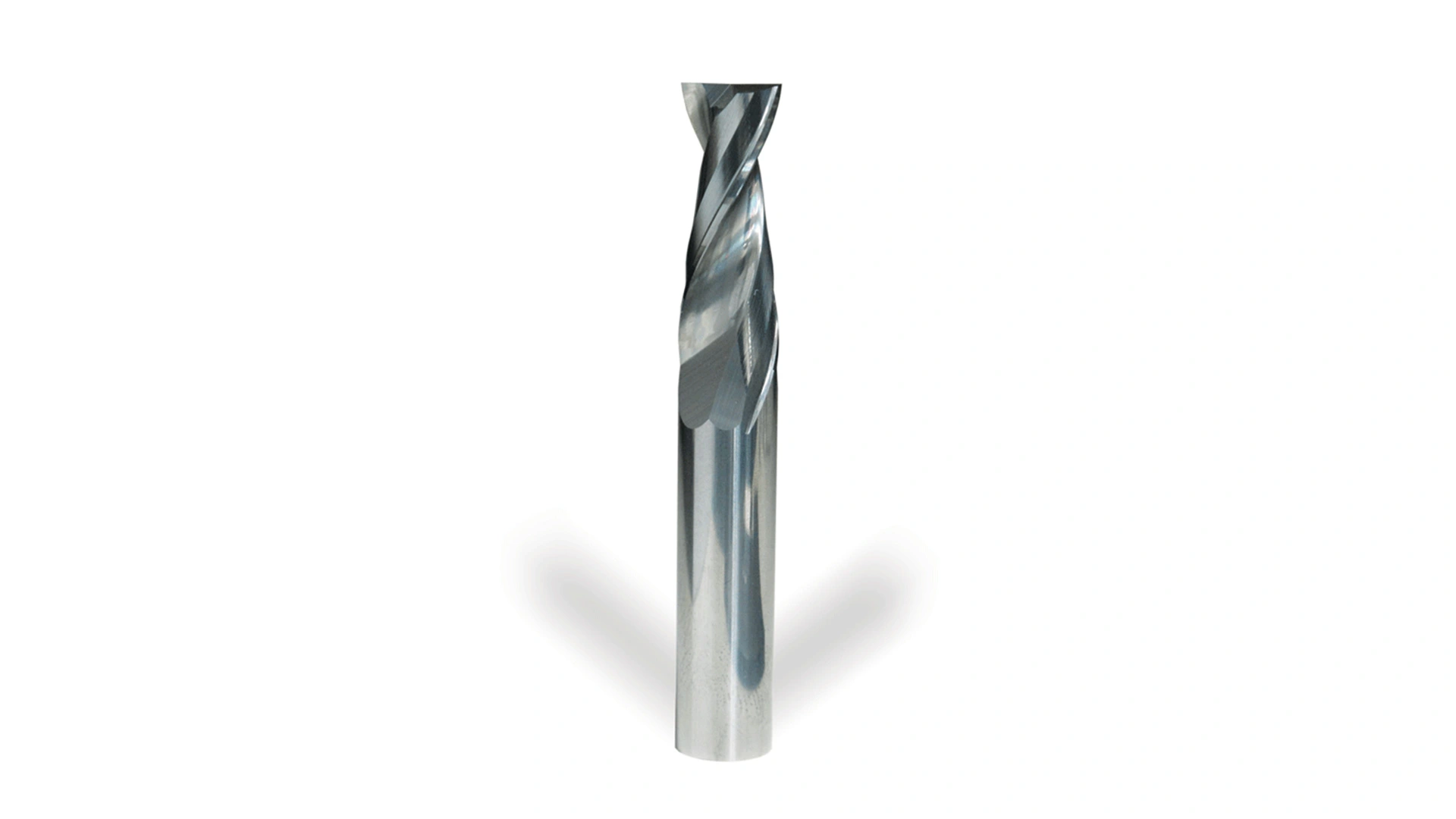

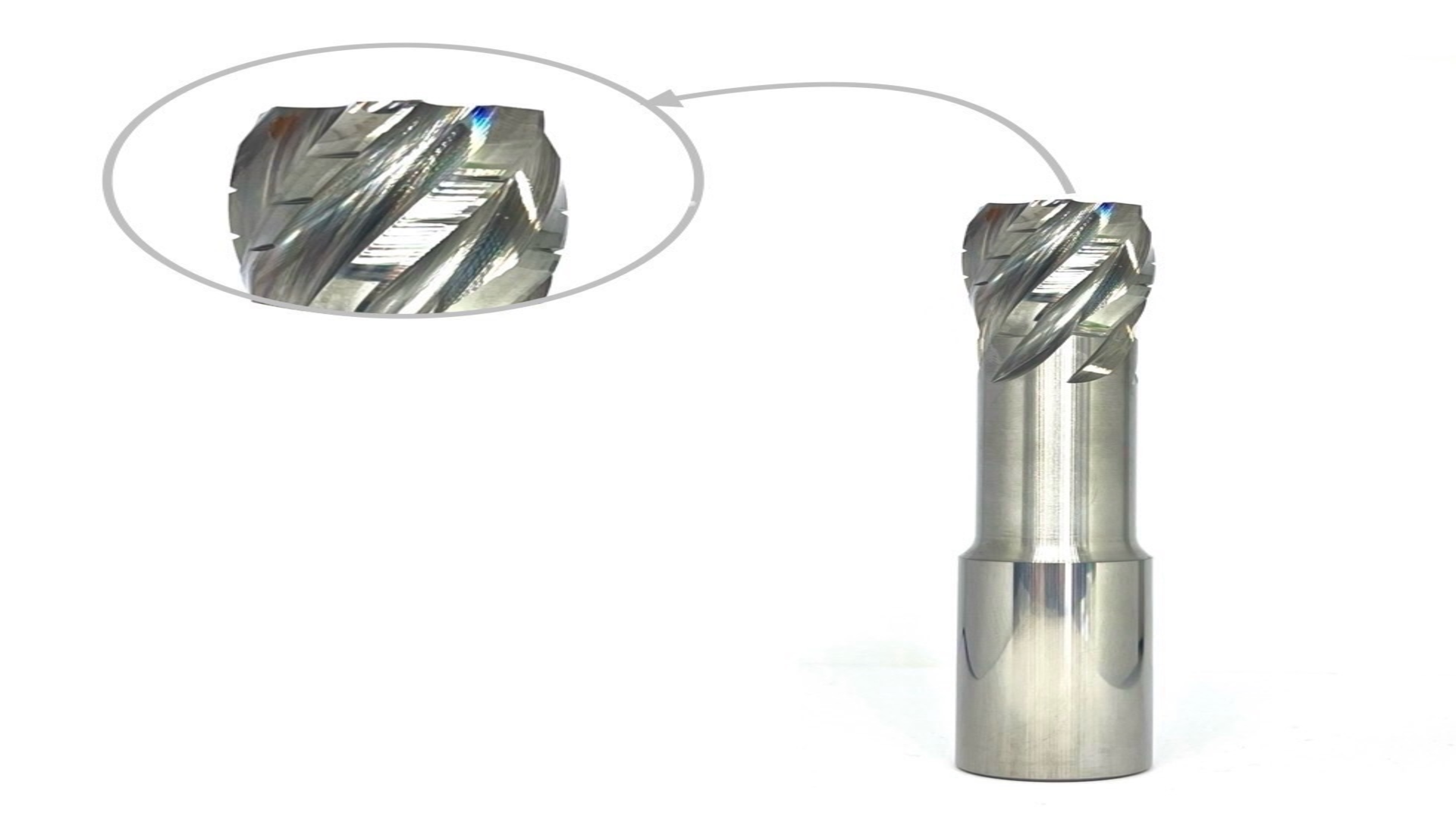

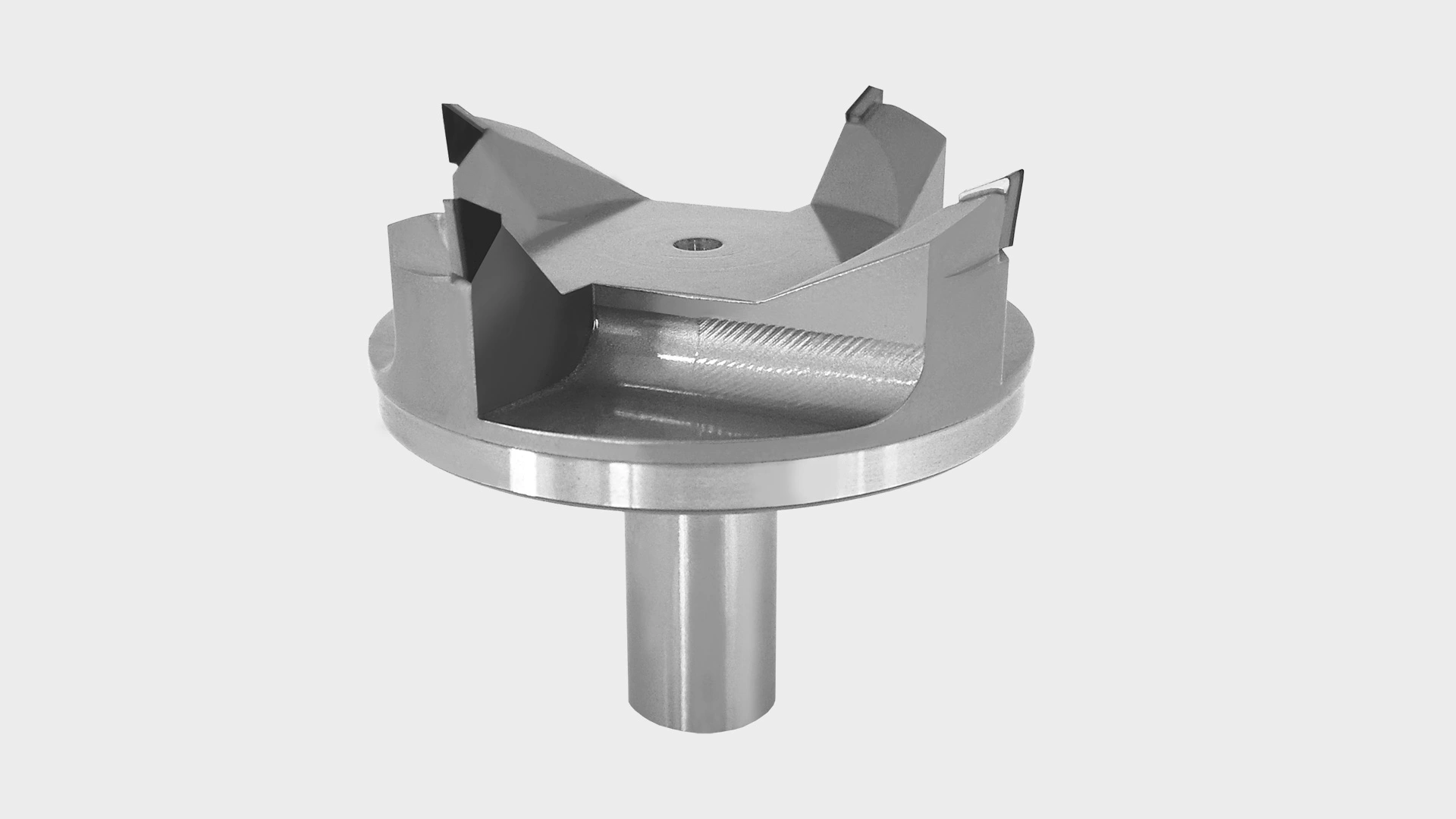

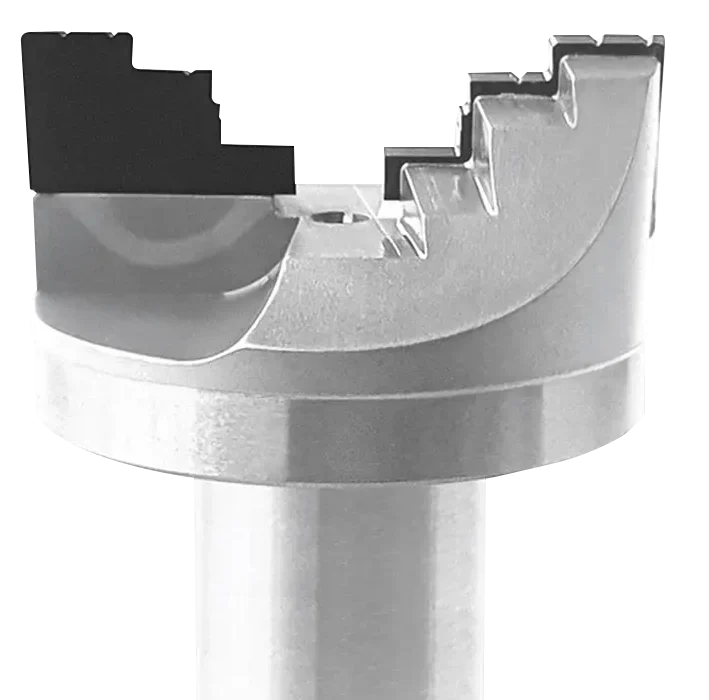

Halcyon is the industry leader in PCD end mill. Our patent pending Z-TEC End Mill technology allows for high-helical PCD on the cutting edges, as well as positive radial rake angle. Our Z-TEC technology eliminates the PCD end mill's limitations on helix angle and cutting length. Its superior performance can achieve 15 times longer tool life than carbide end mill; and 3 times tool life of conventional PCD end mill. This makes it possible for higher feed, better surface roughness, as well as lower cutting force. It reduces cycle time, down time, and ultimately, cost per piece!